William Stopford

2026 BYD Shark 6: More powerful, more capable PHEV ute nears Australia

1 Hour Ago

News Editor

Tesla is reportedly eyeing production of a new US$24,000 (A$35,473) electric car in India.

Reuters reports word from a source with direct knowledge of the matter that executives from the American company will meet with India’s commerce minister before the end of this month.

The new entry-level Tesla would be produced in India both for that market as well as export markets. India is now the world’s third largest car market, though electric vehicles account for less than two per cent of overall sales there.

Both vehicles and batteries could be manufactured in India.

It’s not the first time there has been discussion of a Tesla factory in India.

Last month, CEO Elon Musk said he was confident Tesla would be “in India as soon as humanly possible”, and met with the country’s prime minister Narendra Modi.

“We don’t want to jump the gun on an announcement, but I think it’s quite likely we there will be significant investment and relationship with India in the future”, Mr Musk told reporters at the time.

“India has more promise than any other large country in the world,” Mr Musk additionally told reporters from news outlet ANI.

Tesla had previously indicated it would build more affordable next-generation vehicles at the plant it’s constructing in Mexico.

It’s entirely possible this could still be in the cards. Tesla builds the Model Y, for example, in the US, China and Germany.

Indonesia has also been vying to become the next location of a Tesla factory, with Reuters reporting the country’s efforts to woo the American automaker there are ongoing.

Tesla has yet to indicate whether it would consider Indonesia, which is finalising a new set of incentives to attract electric vehicle manufacturers.

A recent report from Chinese outlet LatePost said Tesla’s next-generation vehicles will enter production in Mexico in the first quarter of 2025.

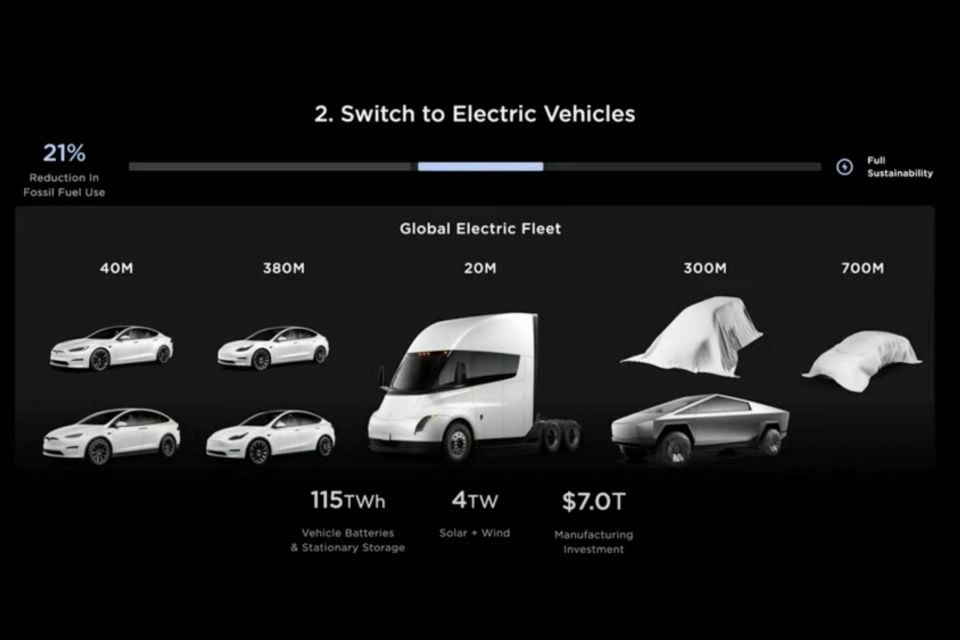

Tesla has confirmed it’s working on a smaller, more affordable vehicle to slot in under the Model 3, as well as a robotaxi.

The company says it already took out 50 per cent of costs from its Model S and Model X to its Model 3 and Model Y, and wants to do it again.

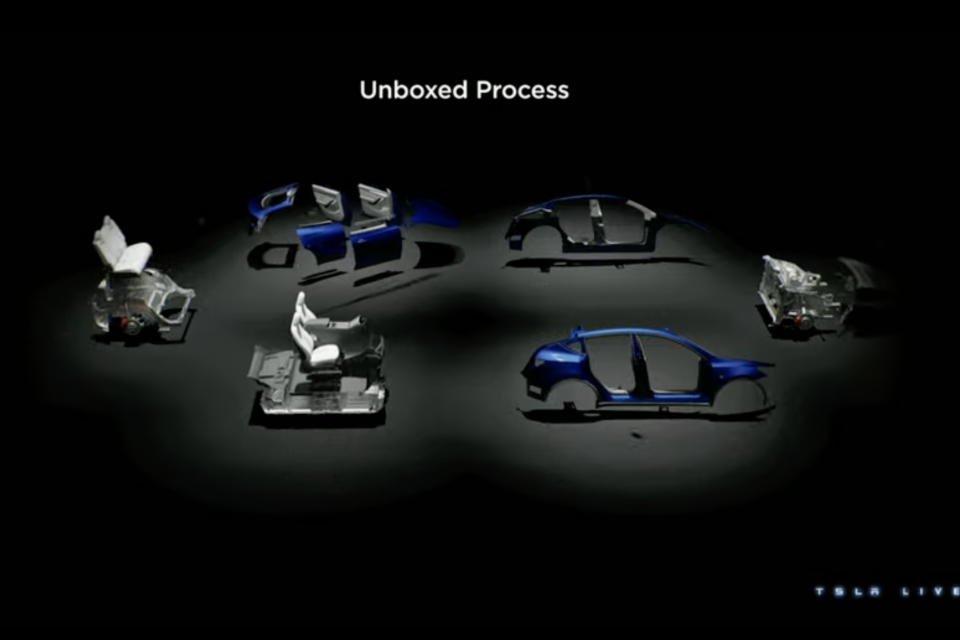

It says past Tesla vehicles were designed first, then engineered, then manufactured. But with the next-generation model, it wants to bring the design, engineering and manufacturing teams together at the beginning.

The company pointed out the inefficiencies of the traditional way of manufacturing a vehicle, saying it’s at “the tail end of its manufacturing optimisation” just over 100 years since Henry Ford opened his first assembly line.

Tesla has reportedly given suppliers a target to start localised production in Mexico before 2025, or risk losing orders for not only parts for Mexican-built Teslas, but also those vehicles built in the US.

LatePost reports more than 20 of Tesla’s Chinese suppliers have announced plans to build factories in Mexico, or have already built factories there in preparation for the new vehicles.

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

William Stopford is an automotive journalist with a passion for mainstream cars, automotive history and overseas auto markets.

William Stopford

1 Hour Ago

Derek Fung

5 Hours Ago

Ben Zachariah

11 Hours Ago

Ben Zachariah

11 Hours Ago

Matt Campbell

11 Hours Ago

William Stopford

18 Hours Ago