Ben Zachariah

Police issue warning against popular 4x4 accessory

2 Minutes Ago

Senior Contributor

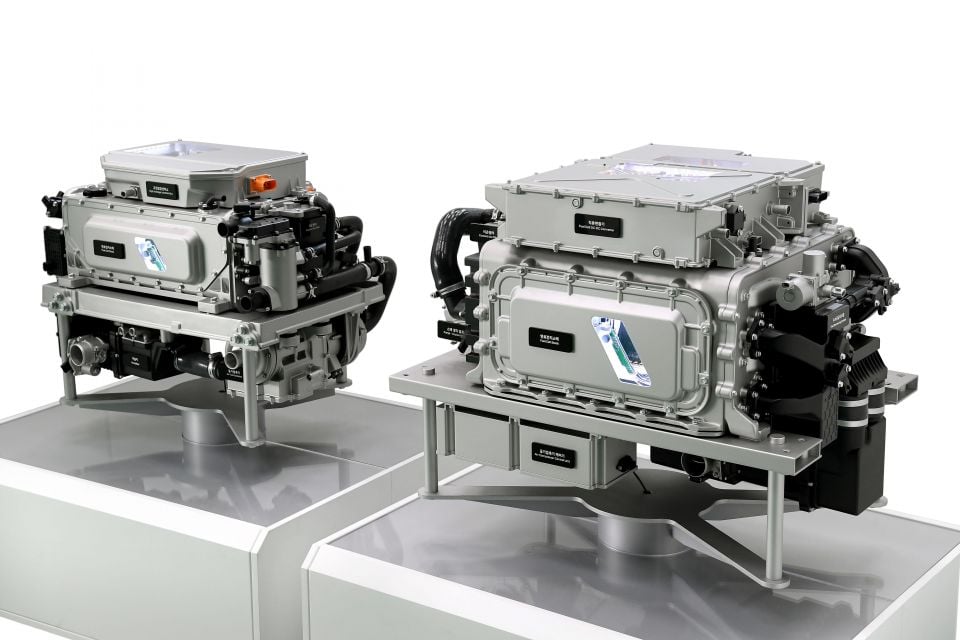

Hyundai Motor plans to launch a cheaper next-generation hydrogen fuel-cell drive unit in 2023, and from there to drastically ramp up production and broaden its use.

The company today said a new Nexo and a fuel-cell version of the Staria people-mover would enter production around this time, as would an updated version of the XCIENT truck.

Hyundai expects its 2023 FCEV ‘stack’, by far the most expensive part, to be some 50 per cent cheaper than current versions due to reduced reliance on materials like graphite and platinum.

From there, in an industry first, it plans for its full range of commercial trucks and buses to come with both hydrogen fuel-cell electric (FCEV) and battery electric (BEV) drivetrains from 2028.

The big goal is price competitiveness between the two zero-emissions drivetrains as soon as 2030, something that would be accelerated through economies of scale.

Hyundai said today its new fuel-cell system would be 30 per cent smaller than today’s Nexo system with the same power output, “to make it easier to apply to different vehicle types”.

It also plans a modular 200kW commercial FCEV drive unit that’s about the same size as today’s 100kW system. The goal is to also increase the life-cycle of a fuel-cell stack by as much as double, with a commercial target of 500,000km total use.

In more exciting news Hyundai R&D head Albert Biermann also detailed a 500kW, rear-drive and 4.0-second 0-100km/h FCEV-BEV hybrid sports car concept called the Vision FK, pairing Hyundai’s fuel-cell stack with a Rimac Automobili electric system. Hyundai invested in Rimac in 2019.

In a media briefing, Hyundai Motor Group chairman Euisun Chung said hydrogen mobility was a feasible carbon-neutral solution, and encouraged a “shift in the energy paradigm”.

“I’m here today to tell you that hydrogen is a powerful solution for combating climate change. We have long understood the tremendous potential of hydrogen energy,” Mr Chung added.

“… We will promote the complete transition of Korea’s public transportation and logistic systems to hydrogen-based solutions. This will be a good model to follow for countries around the world.”

He’s thinking big, adding the changes in human life from such technological innovation could be “comparable to the industrial revolution and digital revolution”.

Hyundai Motor’s stance on hydrogen largely echoes Toyota’s and BMW’s, but other companies such as the Volkswagen Group have said battery-electric is the answer to zero-emissions transport, in large part because hydrogen refuelling infrastructure lags and because of inherent losses in energy efficiency.

Elon Musk famously called FCEVs “fool cells”.

But the Korean giant says issues around rapid refuelling and long-range driving – especially for commercial vehicles – are better answered by hydrogen, and that multiple alternatives were essential to get to net-zero emissions transport.

Not just BEVs or FCEVs, but both at huge scale. Hyundai currently produces BEVs such as the Ioniq, Kona and Ioniq 5, and has a whole family of other Ioniq-branded BEVs around the corner on its 800V-capable EV skateboard.

“Many people are skeptical,” admitted Hyundai Motor’s Fuel Cell Centre head Saehoon Kim, but said converting excess green energy into hydrogen for transport made sense as an alternative to storing electricity in batteries – which is where we get into BEV vehicle-to-grid territory.

Mr Kim also said there were plans underway for more hydrogen production and H2 bowsers across Europe, the US and Asia (as well as Australia), and that hydrogen was deemed an essential component of the future energy mix under the European Green Deal.

“Hyundai Motor Group’s vision is to apply hydrogen energy in all areas of life and industry such as our homes, work-places and factories,” added Hyundai Motor chairman Euisun Chung.

“We want to offer practical solutions for the sustainable development of humanity and with these breakthroughs, we aim to help foster a worldwide Hydrogen Society by 2040.”

Background

Hydrogen FCEVs are quite simple. While a BEV stores energy in a battery to power the motor, a FCEV’s stack generates electricity to power the motor for as long as hydrogen fuel is provided. Its sole emission is water.

The mechanism by which it spins the wheels is a chemical reaction in the stack between the hydrogen (ideally produced using renewable electricity) stored in onboard tanks, and atmospheric oxygen. Think of it a bit like reverse electrolysis.

The hydrogen is pumped in pressurised form into a FCEV through a pump much like a petrol bowser, which a refuelling time of just a few minutes and driving range to match petrol or diesel vehicles.

Some of our most recent hydrogen stories can be found here or at the links below.

MORE: Genesis to be electric and hydrogen-only by 2030 MORE: Hyundai teases sporty hydrogen fuel-cell concept MORE: BMW ‘pushing forward’ on hydrogen fuel-cells, starting with X5 MORE: Hydrogen-powered Toyota Corolla and Prius set to launch in 2023

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

Ben Zachariah

2 Minutes Ago

William Stopford

1 Hour Ago

Damion Smy

3 Hours Ago

William Stopford

4 Hours Ago

Damion Smy

5 Hours Ago

Damion Smy

6 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.