Damion Smy

2026 BMW i5 Touring review

6 Hours Ago

LFP, NMC and NCA. These acronyms have all been part of the jargon surrounding electric cars recently. What do they mean, and what’s the difference?

Contributor

Contributor

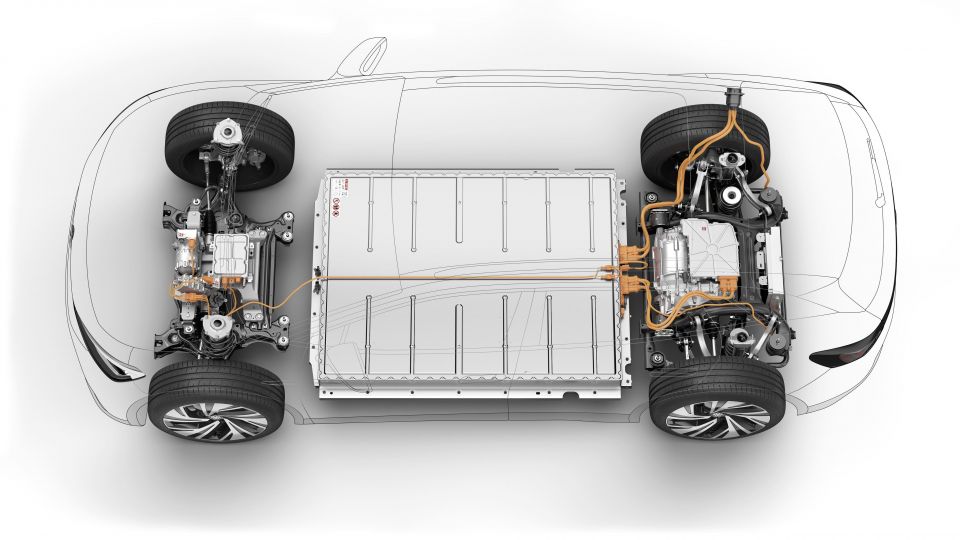

Almost every new electric car (EV) uses lithium-ion batteries, the same basic type of rechargeable battery that powers most phones, laptops, and other handheld devices.

Lithium-ion differs from the lead-acid batteries that were used to power early EVs, and are still often used as 12V batteries on most combustion-engined vehicles.

These batteries are known as lithium-ion because of their fundamental principles of operation. This is explained in more detail here.

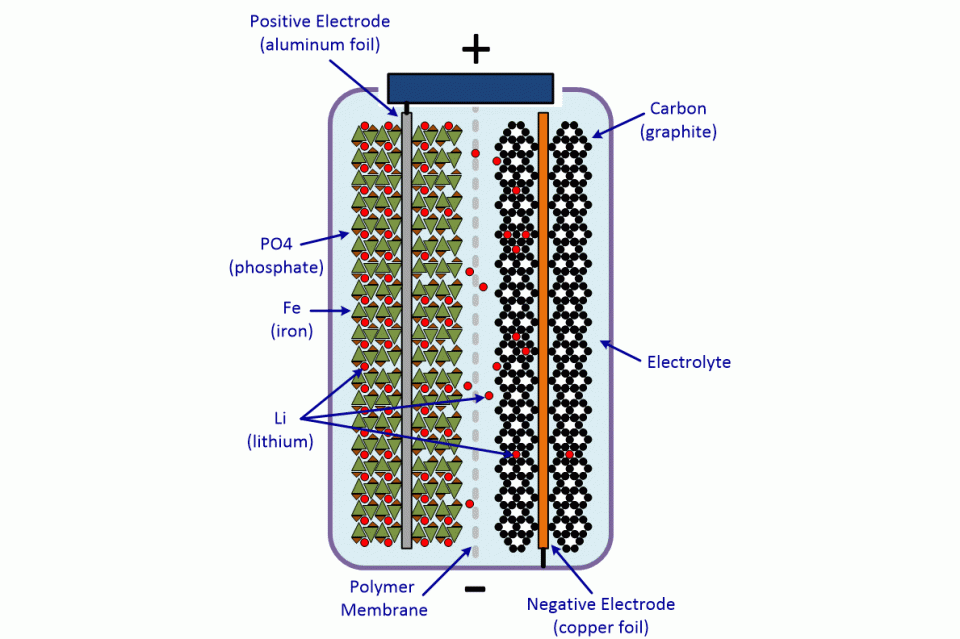

Put simply, a redox reaction caused by the interaction of the battery terminals (anode and cathode) with the electrolyte stimulates the transfer of positively-charged electrons (lithium ions) around the electrical circuit from the anode to the cathode when the battery is being discharged.

In an EV, the circuit is connected to a motor, allowing the vehicle to move as the ions move through it. When the battery is being recharged, the ions flow in the opposite direction from the cathode back to the anode.

Typically, the anode in a lithium-ion cell is made from a carbon-based material such as graphite. The acronyms mentioned above, such as LFP, NMC, and NCA, describe the chemistry of the cathode used to store the lithium.

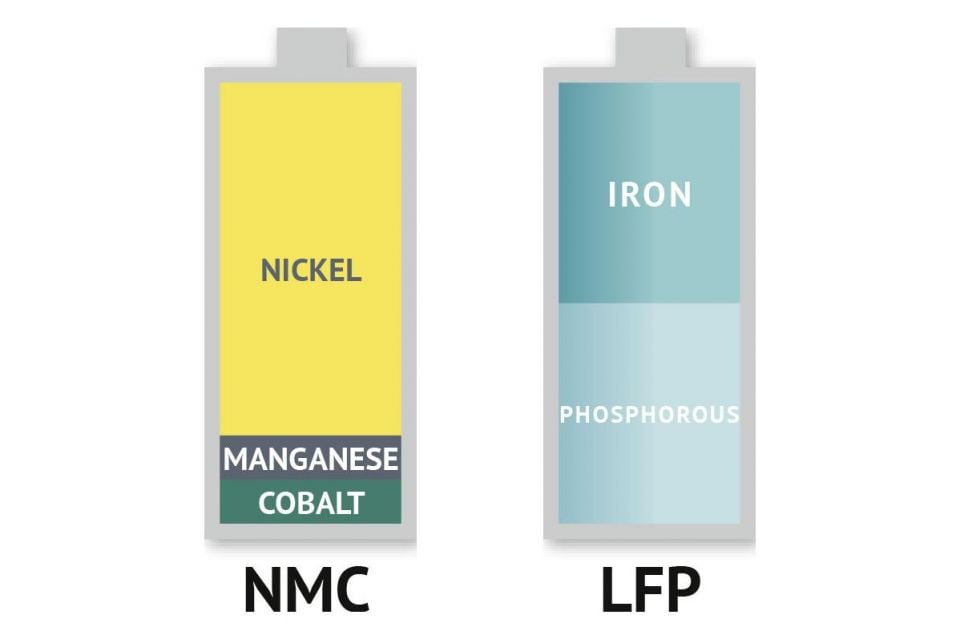

Therefore, LFP equates to lithium-iron-phosphate (the F is derived from Fe, the chemical symbol for iron), NMC refers to nickel-manganese-cobalt, and NCA refers to nickel-cobalt-aluminium, another cathode chemistry. These are all sub-types of lithium-ion batteries.

This story will describe some of the practical benefits and drawbacks of each type of cathode chemistry, and how they can affect the performance and cost of your EV.

Information around the specific type of cathode chemistry used by your EV’s lithium-ion battery can be difficult to come across, but a starting point could be finding out where your vehicle is made.

China is a specialist in the development and manufacture of LFP batteries.

Cars made there, such as newer Tesla Model 3 vehicles and cars from Chinese brands such as BYD, are more likely to use LFP technology.

Volkswagen and Ford are also investigating the use of LFP batteries for certain models.

If your EV is an older model or made outside of China, it may be using an NMC or NCA chemistry rather than LFP.

LFP batteries are generally less energy dense than their NMC and NCA counterparts. On the face of it, this means an LFP battery with an equivalent mass to these rival technologies will be able store less energy and thereby have a reduced range.

While this may be the case initially, a holistic calculation of potential range must also take into account other factors, such as aerodynamics and the energy efficiency of components such as the motors and HVAC system.

It’s in these areas an LFP-based vehicle can compensate for the potential reduction in energy density of the battery.

The Model 3, for example, features excellent aerodynamics with a low coefficient of drag (0.23 Cd) and a heat pump to maximise the efficiency of the heater in cold weather, ensuring there’s less of an impact on range when production switched to an LFP battery after moving to China.

Manufacturers can also compensate for the reduction in energy density by simply adding in more capacity, although of all the battery types an LFP one would will be heaviest with the same capacity as NMC and NCA batteries.

Weight is the ultimate adversary of an electric vehicle, compromising everything from range to dynamics. In this regard, non-LFP battery chemistries may hold an advantage.

Initial reports of customers driving LFP Model 3 vehicles in Europe also reported issues with cold-weather range and fast charging performance, but this is likely an issue with software calibration rather than the physical characteristics of the LFP battery itself.

NMC and NCA battery chemistries use rare earth material such as cobalt and nickel that are in limited supply.

They’re also expensive and environmentally ruinous to mine. The Democratic Republic of Congo accounted for 100,000 tonnes, or 70 per cent of the world’s cobalt production in 2019, but has a poor track record for human rights, with cobalt supply chain workers suffering from inhumane conditions.

LFP, in comparison, uses iron and phosphate, both of which are far more common and easier to source, which in turn makes them cheaper to produce, facilitating cost savings that can be passed on to customers… or shareholders.

An equally practical advantage is that LFP batteries are able to be regularly charged to 100 per cent without adversely affecting the long-term lifespan of the battery.

In contrast, for typical NMC or NCA batteries, manufacturers generally recommend only charging to 100 per cent occasionally – such as for longer road trips – to preserve battery life.

Damion Smy

6 Hours Ago

William Stopford

13 Hours Ago

Paul Maric

14 Hours Ago

Damion Smy

14 Hours Ago

Damion Smy

17 Hours Ago

William Stopford

17 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.