Damion Smy

BYD sues US government over Trump tariffs blocking Chinese EVs – report

1 Hour Ago

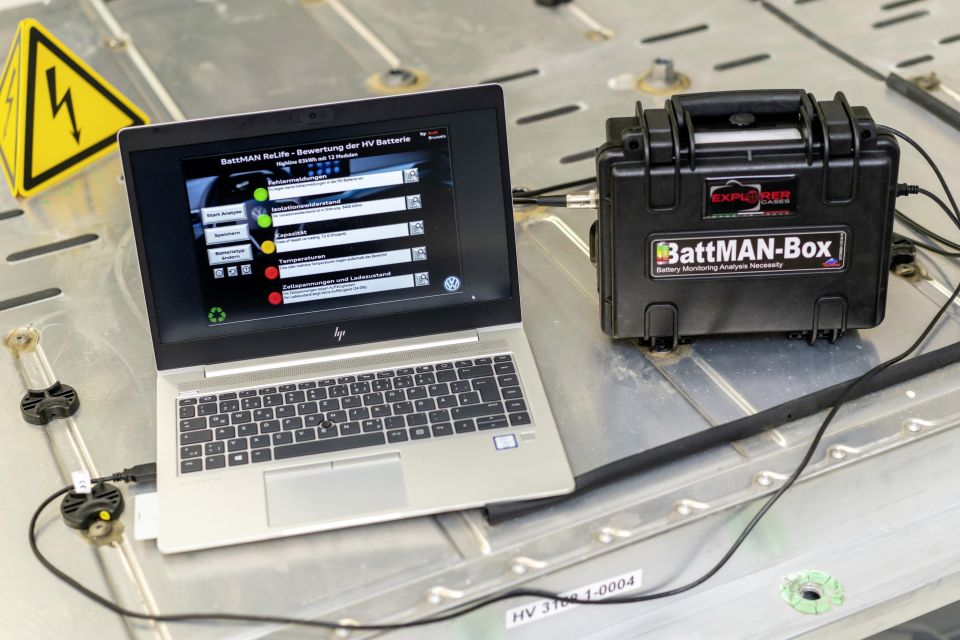

The BattMan ReLife battery analytic software is said to help diagnose the health and life of Volkswagen Group EV batteries.

Contributor

Contributor

Wondering if there’s life left in your lithium-ion battery pack? BattMan is here to save the day!

The Battery Monitoring Analysis Necessity (BattMan) tool is a quick check system that helps the Volkswagen Group understand if an electric vehicle’s (EV) lithium-ion battery can be repurposed or recycled.

BattMan was first developed to help check the health and life of the high-voltage battery used in the Audi e-tron.

After its initial success, BattMan went into further development with recycling experts from Volkswagen Group Components and was rebranded as the BattMan ReLife.

This new-generation analytic software is able to provide an initial health assessment of an EV battery in a few minutes, rather than the several hours it took the previous version.

It is set to be used at the Volkswagen Group Component’s first battery recycling pilot plant in Salzgitter, Germany.

Experts plug the BattMan device into a vehicle’s low-voltage connectors, and it does the rest automatically.

Initially, the device checks whether the EV battery is able to send and receive data.

It then checks to see whether there are any error messages, and confirms the insulation resistance, capacity, temperatures, and cell voltages.

“We are able to measure all a cell’s most important parameters,” said Axel Vanden Brande, quality engineer at Audi Brussels.

“Then a traffic light system indicates the status cell by cell – green means a cell is in good order, yellow means it requires closer inspection, and red means the cell is out of order.”

Once the battery test has concluded, the company has laid out three options for its end-of-life EV batteries.

If the battery is in good health, it can be reused in another Volkswagen Group electric car.

If it’s not good enough to be used in another vehicle, the battery can be sent off to be refurbished and be implemented in something else.

The company says these batteries might be used in a quick charging station, a robot, an autonomous transport vehicle, a forklift, or a home power system.

The final option for low-health EV batteries is recycling at Volkswagen Group Components pilot Salzgitter recycling plant.

Volkswagen Group engineers extract basic materials like aluminium, copper, plastics and so-called ‘black powder’. This powder contains materials such as lithium, nickel, manganese, cobalt, and graphite, which can all be used again in new batteries.

“We know that recycled battery materials are just as effective as new ones,” said Frank Blome, Head of Battery Cell and Battery System at Volkswagen Group Components.

“These recycled materials will be used to supply our cell production activities in the future.”

MORE: Everything Audi E-Tron

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

Jack Quick is an automotive journalist based in Melbourne. Jack studied journalism and photography at Deakin University in Burwood, and previously represented the university in dance nationally. In his spare time, he loves to pump Charli XCX and play a bit of Grand Theft Auto. He’s also the proud owner of a blue, manual 2020 Suzuki Jimny.

Damion Smy

1 Hour Ago

William Stopford

2 Hours Ago

Damion Smy

3 Hours Ago

Damion Smy

4 Hours Ago

William Stopford

4 Hours Ago

Derek Fung

7 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.