Josh Nevett

2026 Zeekr 009 review

6 Hours Ago

Emissions regulations are becoming increasingly stringent. Particulate filters are one technology car-makers are using to meet these targets.

Contributor

Contributor

‘DPF’ and ‘PPF’ are acronyms that are increasingly becoming common parlance in the automotive industry today.

These abbreviations describe related technologies that reduce the level of harmful emissions exiting the tailpipe of petrol and diesel powered cars, and thereby meet increasingly strict regulations around the world that aim to minimise air pollution.

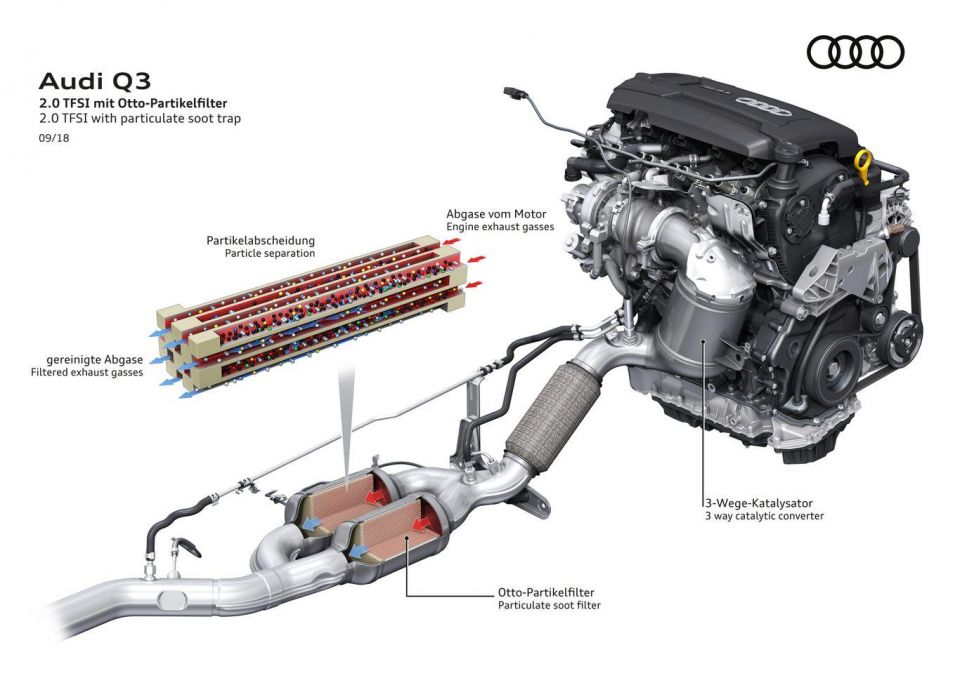

Most new cars sold today with a diesel engine are equipped with a DPF (Diesel Particulate Filter). In Europe especially, petrol powered new cars are also being equipped with a PPF (Petrol Particulate Filter) to further control emissions.

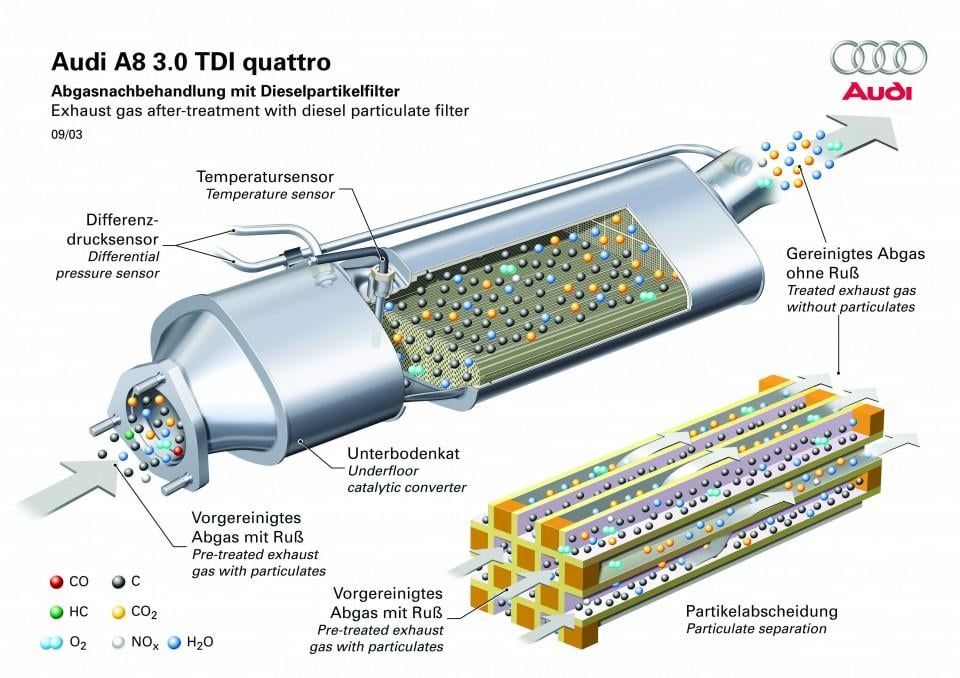

The burning of diesel fuel in the combustion chamber of an engine results in the generation of various byproducts including soot (technically known as DPM, or Diesel Particulate Matter), that when released into the atmosphere can be a significant contributor to air pollution.

The primary purpose of a DPF is to filter out this soot, and other harmful particulates, from the gases generated during combustion.

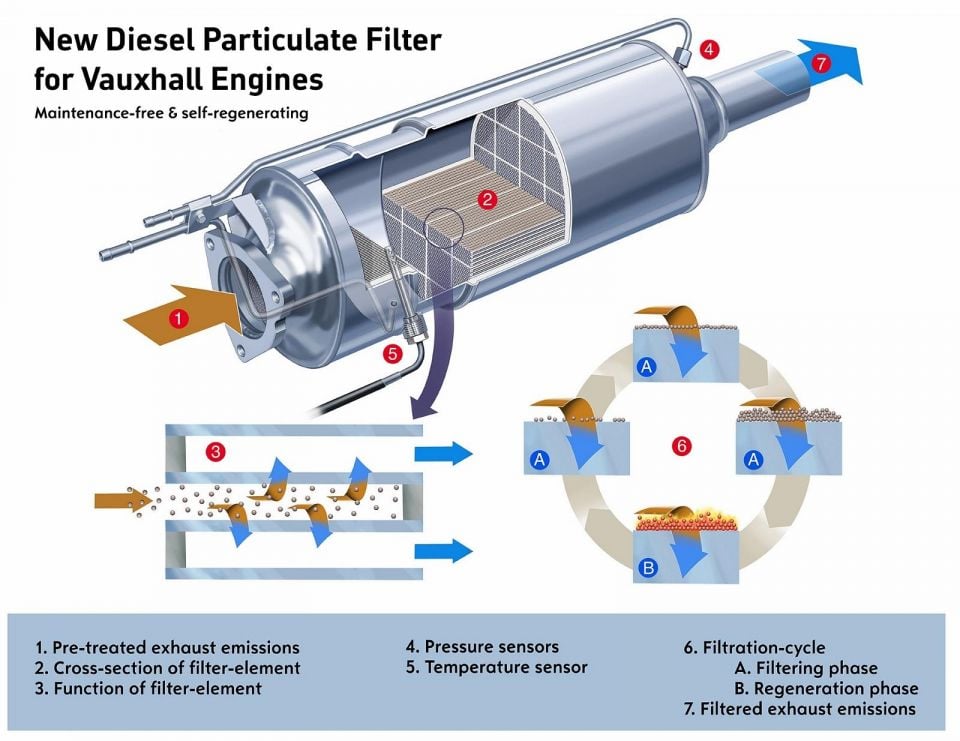

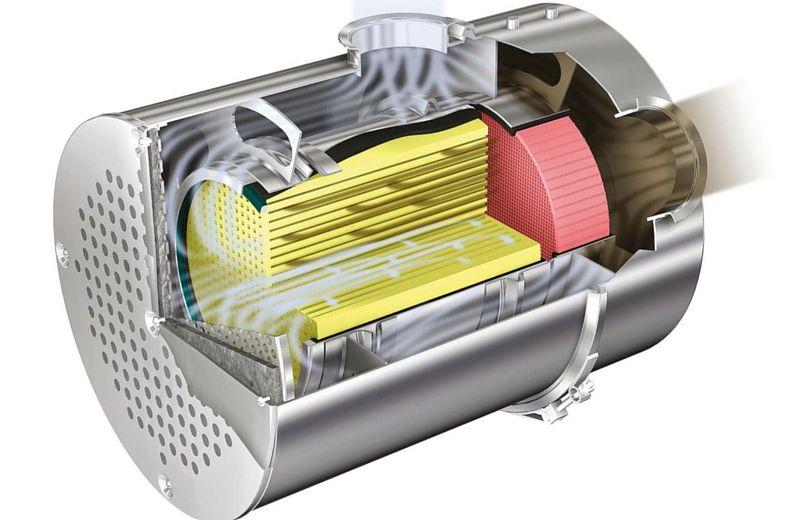

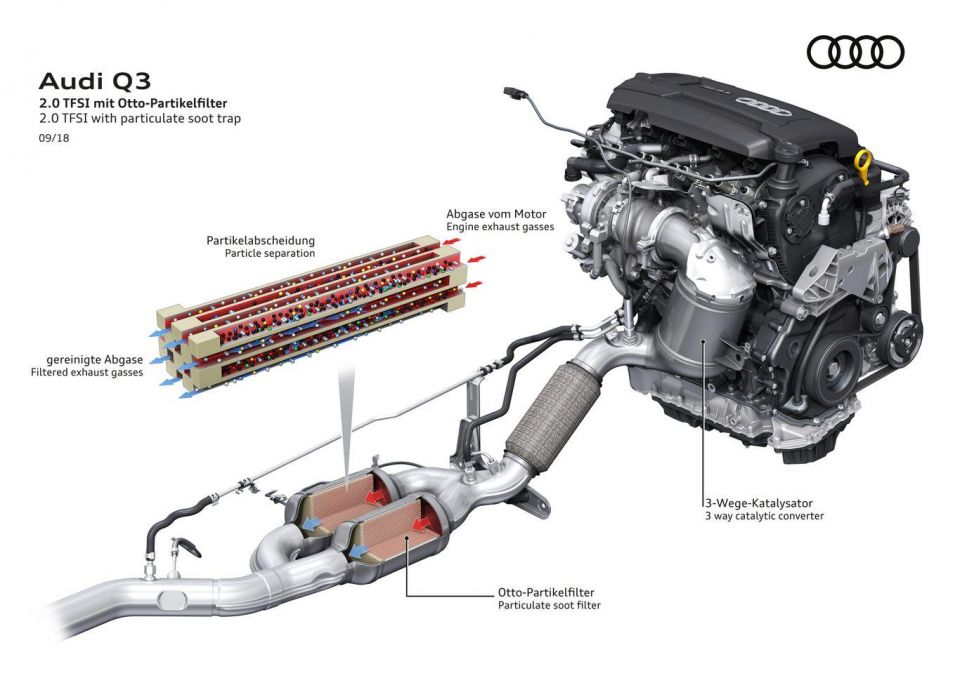

A DPF is a metal, cylindrical, tube-like device incorporated within the car’s exhaust system, which can be located before or after the catalytic converter. It consists of three key parts.

The most critical of these is a honeycomb-style filter that does the substantive work of trapping soot within the DPF. This filter, known as a ‘wall-flow’ or ‘flow-through’ filter, can be made from various substances, including silicon-based materials such as cordierite and silicon carbide, or from metal fibres.

A DPF also makes use of a temperature sensor, and a differential pressure sensor, both connected to the car’s ECU (Engine Control Unit).

When particulate-heavy gasses from the engine enter the DPF, microscopic channels within the filter are able to trap these particles, preventing them from reaching the vehicle’s tailpipe and thereby being emitted into the surrounding environment.

Much like how a vacuum will only function properly if it is using a clean dust filter, a DPF works best when the filter is not clogged up.

Thus, for it to function effectively, the car needs to know the extent to which the DPF is filled with soot and other particulates, and then have a process to clean the filter so it continues to function as designed. This is known as regeneration.

The differential pressure sensor is able to measure and compare the difference in the pressure of the exhaust gas as it enters and leaves the DPF. The car’s ECU takes these readings and combines them with other parameters such as the volume of intake air, engine load and level of injected fuel to calculate how much particulate matter is in the filter.

Over the course of normal driving situations, such as highway driving over reasonably long distances, the DPF is able to clean itself during normal operation through spontaneous, or passive, regeneration.

In these instances the DPF reaches temperatures of anywhere between 350-500 degrees C, and this is adequate for soot in the filter to be burned off and converted into carbon dioxide.

If spontaneous regeneration is inadequate to clear the filter, the ECU can intervene directly in what is known as dynamic, or active, regeneration.

During dynamic regeneration, extra fuel is injected into the combustion chamber, which has the effect of raising the exhaust gas (and thereby DPF filter) temperature to approximately 600C, thereby further burning away soot and other particulates.

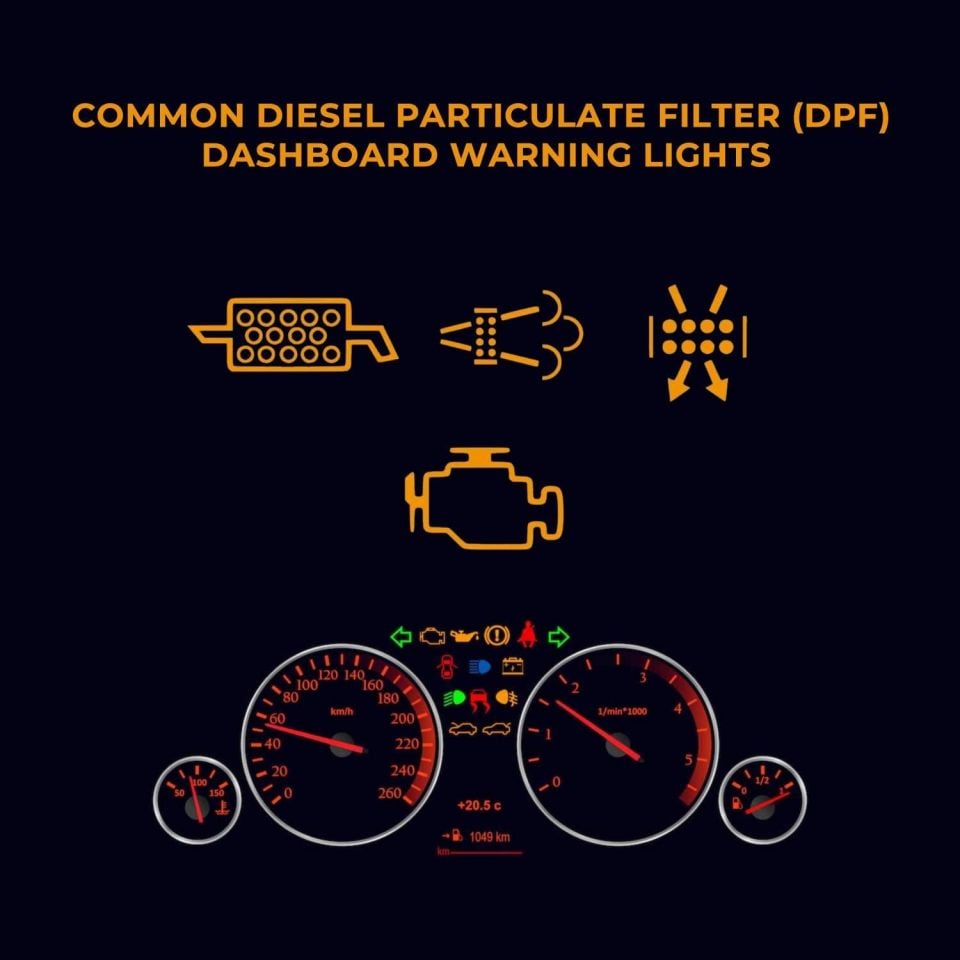

In this situation, a DPF warning light may illuminate in the car’s instrument cluster to indicate that the ECU has initiated a dynamic regeneration process. Ideally, the vehicle should continue to be driven until the DPF light is no longer illuminated.

A flashing DPF light in a car’s instrument cluster may occur if the dynamic regeneration process is continually interrupted, e.g. if the car makes numerous short trips or if the dynamic regeneration is otherwise unable to clear the DPF of soot.

If this is the case, a service regeneration may be needed. A service generation is carried out at a workshop or service centre, and the vehicle remains stationary during this time. The car is connected to a diagnostics computer, and the ECU is programmed to add in even more fuel into the combustion chamber, through post-injection fuel pulses, to further raise the exhaust gas temperature and facilitate burning of the particulate matter within the filter.

Continually ignoring any DPF warning lights in the instrument cluster may cause the DPF to fail entirely, consequently necessitating a replacement.

A petrol particulate filter works on the same underlying principle as a diesel particulate filter.

However, as the combustion of petrol generally produces less soot and particulate matter than diesel, PPFs are generally able to spontaneously/passively regenerate far more effectively than DPFs, and in most cases do not require the ECU to intervene in a special active or service regeneration mode.

A key issue to note is that vehicles equipped with petrol particulate filters are compatible only with low-sulphur petrol, typically with a maximum sulphur amount of 50 PPM (parts per million).

In Australia, this means that owners of cars equipped with petrol particulate filters must only refuel with premium (95 or 98 octane) petrol, as our standard 91 and E10 unleaded fuel is of poorer quality, having a maximum sulphur content of 150 PPM.

Australia’s adoption of Euro 5 emissions standards in November 2016 necessitated a significant reduction in particulate matter emissions for diesel engines, and the most practical way for car-makers to comply with this standard was through the inclusion of a DPF device. Thus, most new diesel cars sold since then have been equipped (and continue to be equipped) with a DPF.

Although car-makers now have several years of experience with DPFs, this is not necessarily a guarantee of their quality or reliability. Most recently, a class-action lawsuit was filed against Toyota, with owners claiming that DPF devices in various HiLux, Fortuner and Prado models were defective by not regenerating during normal urban driving scenarios.

Toyota responded by allowing owners to take their cars back to the dealership for an engine software update, and also introducing a manual DPF generation button on models sold after mid-2018. A facelift for MY21 models further improved DPF performance through various additional hardware and software changes.

In contrast, cars equipped with PPFs are a more recent phenomenon, and remain very niche in Australia. Peugeot was the first car-maker to introduce a PPF, equipping it on Australian-delivered 308 and 508 GT models towards the end of 2019.

The Volkswagen Group has also introduced the technology in Australia, equipping it on models such as the Audi RS3, Skoda Karoq Sportline and the Skoda Superb Scout.

MORE: We have pages of these technical explainer articles, all located here

Josh Nevett

6 Hours Ago

Derek Fung

21 Hours Ago

Josh Nevett

21 Hours Ago

Alborz Fallah

22 Hours Ago

William Stopford

22 Hours Ago

Andrew Maclean

1 Day Ago