Max Davies

2026 Kia Carnival review

4 Hours Ago

News Editor

Nissan is celebrating 35 years of UK manufacturing with something old, something new, something borrowed, and something blue (and pink and green).

The company has created a one-off electric restomod that’s a combination of its very first UK-built model and one of its current UK-built models.

Dubbed the Newbird, Nissan’s project car features the electric powertrain of the Leaf inside a Bluebird hatchback.

That includes the Leaf’s electric motor, inverter, and 40kWh battery pack, with battery modules split between the engine bay and boot to aid weight distribution.

The power steering, braking and heating systems were updated to be electrically-powered, while the Newbird rides on a custom suspension that’s been designed to support the additional weight from the battery packs.

Open the fuel filler door and you’ll now find a charging port, and the battery can be charged at up to 6.6kW.

The fuel gauge in the instrument cluster now shows the battery’s state of charge, while the shifter has been replaced. Otherwise, the interior is essentially unchanged from the first UK-built Bluebird, though sadly not one with the cushy velour trim so in vogue at the time in Japanese cars.

As this is a one-off, it hasn’t been homologated but features an estimated range of 209km and a 0-100km/h time of under 15 seconds.

Nissan Design Europe says the colourful livery is “inspired by design cues of 1980s consumer technology, combined with a 21st century aesthetic”. We think it’s as 80s-tastic as leg warmers and crimped hair.

The badge up front also receives LED backlighting, though we doubt you’d be able to miss this colourful Bluebird out on the street.

Nissan conducted the conversion with Kinghorn Electric Vehicles, based just 15 miles up the road from Sunderland, which specialises in classic car EV conversions using recycled Leaf components.

“When Nissan opened the Sunderland factory it gave the North East a big economic boost. The Bluebird was first off the line, so it represents the start of that optimism, progress and global industrial footprint that’s continued to this day,” said Kinghorn Electric Vehicles managing director George Kinghorn.

Nissan has produced over 10.5 million vehicles at Sunderland since it opened in September 1986, with the number of staff growing from 430 to 6000. The company says there are still 19 staff members still on the payroll who have been there since it opened.

While some companies have ended manufacturing in the UK, Nissan has committed to the market.

Earlier this year it announced plans for a £1 billion ($1.8 billion) electric vehicle hub in Sunderland, including a nine gigawatt-hour battery factory and a plant which will build up to 100,000 electric cars every year.

Nissan’s new battery factory will be able to produce 9GWh of batteries every year, more than four times the capability of Nissan’s current Sunderland site.

The batteries will be Nissan’s new Gen5 cells, which the company says offer 30 per cent more energy density than its current lithium-ion batteries.

MORE: Nissan announces $24.6 billion electrification plans, four EV concepts

Nissan says there’s potential to expand the site’s capacity to 25GWh by 2030, and it could eventually match the Tesla gigafactory in Nevada with a 35GWh capacity.

The company says the plant will initially create 750 new jobs and safeguard 300 more.

Powering the electric car hub will be a zero-emissions ‘microgrid’ using second-life battery packs for energy storage. It’s part of a Sunderland City Council project forecast to save 55,000 tonnes of carbon every year.

Nissan is also installing a new 20MW solar farm to join the plant’s existing wind and solar farms.

The move to use the UK as a battery manufacturing hub is a big win for the manufacturing sector, which has been rocked by multiple plant closures in the past few years.

Nissan itself has stopped building the X-Trail in Sunderland due to uncertainty caused by Brexit, although the Leaf, Juke, and Qashqai are all still made in the UK.

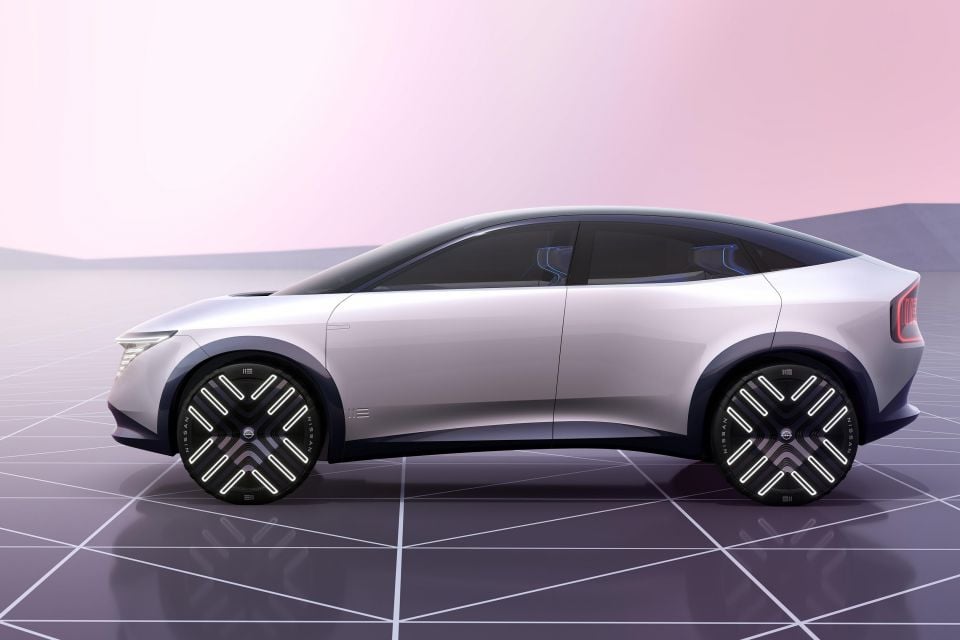

It’ll also build a new electric crossover there, previewed by the Chill-Out concept.

The first car to roll off the Sunderland line was the front-wheel drive T12/T72 Bluebird in 1986.

It replaced another front-wheel drive model called the (U11) Bluebird, launched in 1984, which continued to be sold in markets like New Zealand and spawned a six-cylinder version wearing the Maxima nameplate in North America.

The UK-built Bluebird was a version of the related Japanese-market T12 Auster, also sold in the US market as the Stanza.

We didn’t receive any of these front-wheel drive, mid-sized Nissans in Australia. The dated rear-wheel drive Bluebird continued here until 1986, after which it was replaced by the R31 Skyline-derived, four-cylinder Pintara.

In 1990, Nissan replaced the Bluebird in the UK with the well-received Primera, also built in Sunderland, while we received the considerably less well-received Pintara – an Aussie-built version of the U12 Bluebird – in 1989.

Nissan is the latest company to release an electric restomod of one of the consequential models of its past. Hyundai has done the same, showcasing electric conversions of its first-generation Pony and Grandeur.

Click the images to view the full gallery.

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

William Stopford is an automotive journalist with a passion for mainstream cars, automotive history and overseas auto markets.

Max Davies

4 Hours Ago

Damion Smy

20 Hours Ago

William Stopford

20 Hours Ago

William Stopford

20 Hours Ago

Derek Fung

22 Hours Ago

Ben Zachariah

1 Day Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.