Ben Zachariah

2026 KGM Musso EV review

2 Hours Ago

That new BMW or Jaguar you bought must have been built by, you know, BMW or Jaguar – right? Think again. Magna is the ‘behind the scenes’ car brand.

Contributor

Contributor

Without thinking, what countries are the hotspots for the global automotive industry?

Nations such as Germany, Japan, the USA, and China might immediately come to mind. After all, most of the major car manufacturers are based in one of these countries, and they also constitute some of the largest markets for OEMs.

Two places that initially might not appear to carry much significance in this regard are Canada and Austria. However, these countries are home to one of the most important suppliers in the automotive industry – Magna International, and its Austrian subsidiary, Magna Steyr.

Much like competitors Continental and ZF, Magna has dipped its toes into developing and manufacturing a wide range of discrete automotive parts. The company produces everything from headlights to transmissions, active safety systems, and even interior components such as seats.

Where the company differs from other suppliers is its vehicle production business. Think of Magna as a manufacturer without its own badge. The firm is the only major supplier with the scale and expertise for complete vehicle development.

Magna acts as a contract manufacturer for OEMs including BMW, Mercedes-Benz, Toyota (the new Supra is a prime example), Jaguar and others.

What this means is OEMs such as those named above outsource the production of certain models to Magna.

Magna then makes these cars on their behalf, puts the requisite badge on the bonnet and delivers the completed vehicles to the OEM for them to sell to dealerships and customers. These complete vehicles are made in the Magna Steyr plant in Graz, Austria.

The company’s work in complete vehicle production and manufacture of other parts has enabled it to become the third largest supplier based on sales revenue to automotive OEMs (2018 numbers), ahead of Continental and behind Japanese company Denso.

And just to be clear – Magna the supplier has no relationship with the Mitsubishi Magna sedan, formerly a competitor to the Toyota Camry.

Magna traces its roots to the late 1950s. In 1957, Austrian emigrant and entrepreneur Frank Stronach opened a tool and die shop in Toronto, known as Multimatic.

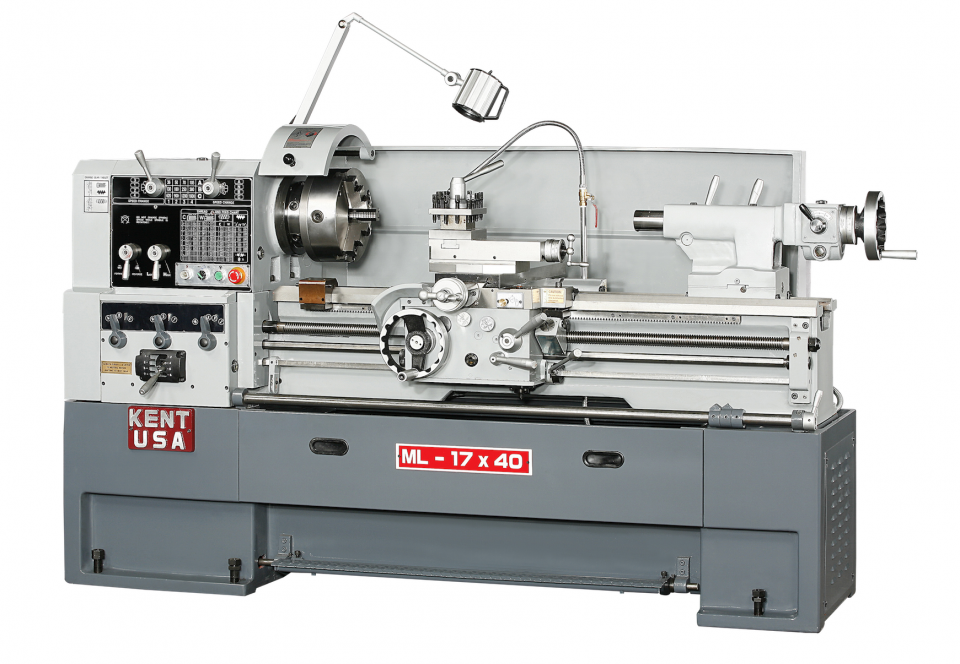

Back then, these shops were specialist machining and manufacturing businesses. Companies would provide the shop engineering drawings on paper, and it was the toolmaker’s job to use the machines at their disposal, such as a lathe, to make a mould of the part and subsequently manufacture it to the specification provided.

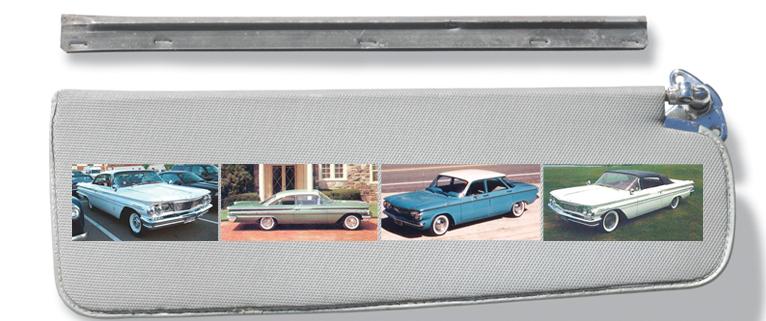

Multimatic was awarded its first automotive contract by General Motors, which commissioned it to produce metal brackets to hold visors for various Canadian market models in 1959.

The 1960s are commonly referred to as the Swinging Sixties, with an optimistic vibe setting the tone for the decade, brought about by the hipster movement and the relaxation of old-fashioned cultural taboos. In a sense, this decade was a happy period of expansion and growth for Magna as well.

In 1965, Canada and the United States signed the Canada – United States Automotive Products Agreement, popularly known as the “Auto Pact” or APTA. This was effectively a restricted trade agreement between the two countries specifically for the automotive industry.

It removed previous Canadian tariffs for American-built vehicles and parts. In exchange, American automakers and suppliers had to guarantee Canadian vehicle production would not fall below 1964 levels, and American vehicles sold in Canada would have a defined proportion of Canadian components.

This gave Multimatic the impetus to start exporting parts to America, commencing with a drip rail for Ford, and allowed the company to expand production over the course of the decade.

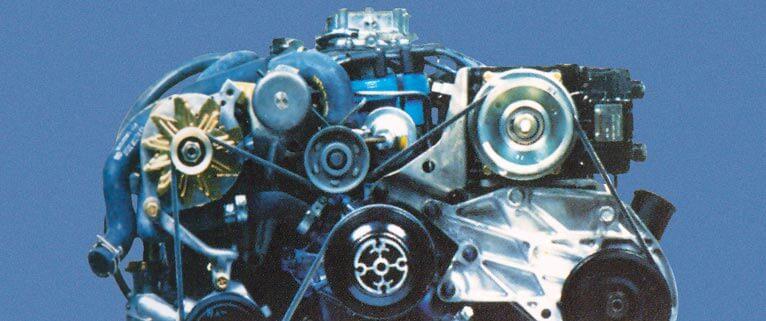

The company obtained its current name from a subsequent 1969 merger with publicly listed defence contractor Magna Electronics Corporation. The ’70s saw it diversify its business further, starting production of various mechanical automotive components, such as oil strainers and developing innovations such as the invention of the single-belt pulley system commonly found on engines today.

The ’90s saw perhaps the greatest expansion of the company’s capabilities, through the acquisition of Steyr-Daimler-Puch (now Austrian subsidiary Magna Steyr) and its automotive manufacturing facilities in 1998. The word “Daimler” provides a small hint at Steyr’s origins – it was a very distant cousin of the modern Daimler AG (manufacturer of Mercedes-Benz cars today).

Magna’s current vehicle portfolio comprises the new Toyota Supra, the BMW Z4 and 5 Series (5 Series production is split between Magna and BMW factories) as well as the Jaguar I-Pace and E-Pace. The iconic Mercedes-Benz Geländewagen (G-Class) is also produced by Magna.

Despite being from different marques, these vehicles are all made under the same roof at Magna’s factory in Graz, Austria.

Magna has also made some notable vehicles in the past. These include the Peugeot RCZ with its ‘double bubble’ roof, early production of Aston Martin’s sexy four-door Rapide and previous Jeep Grand Cherokee models.

While Magna currently produces vehicles exclusively at its factory in Austria, the company is expanding its production facilities, with a factory built in partnership with Beijing Electric Vehicle Co in Zhenjiang, China.

This facility will make the Chinese market Arcfox Alpha-T small electric SUV.

The diversity of the automotive parts produced by Magna, together with its complete vehicle production, means the firm has more avenues through which it can innovate. In line with competitors, the company is investing significant resources in autonomous driving technology, as well as electrification.

Two recent innovations that demonstrate the breadth of the company’s expertise are the composite spaceframe and Freeform seat trim covers.

The composite spaceframe is a lightweight plastic that made its debut on the new Toyota Supra. This is the material that enabled Toyota’s designers to form Supra’s heavily curved tailgate, whilst also achieving a 10 per cent weight saving over a comparable steel part.

Freeform, meanwhile, is a seat moulding technology that works with vinyl, fabric, or genuine leather seats to create unique seat forms.

Have you a recently bought a car with heavily sculptured sports seats? They may have been made using Magna’s Freeform manufacturing technology.

Ben Zachariah

2 Hours Ago

James Wong

2 Hours Ago

James Wong

2 Hours Ago

James Wong

2 Hours Ago

Damion Smy

9 Hours Ago

William Stopford

10 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.