James Wong

Subaru plans hybrid expansion in Australia – what's next?

1 Hour Ago

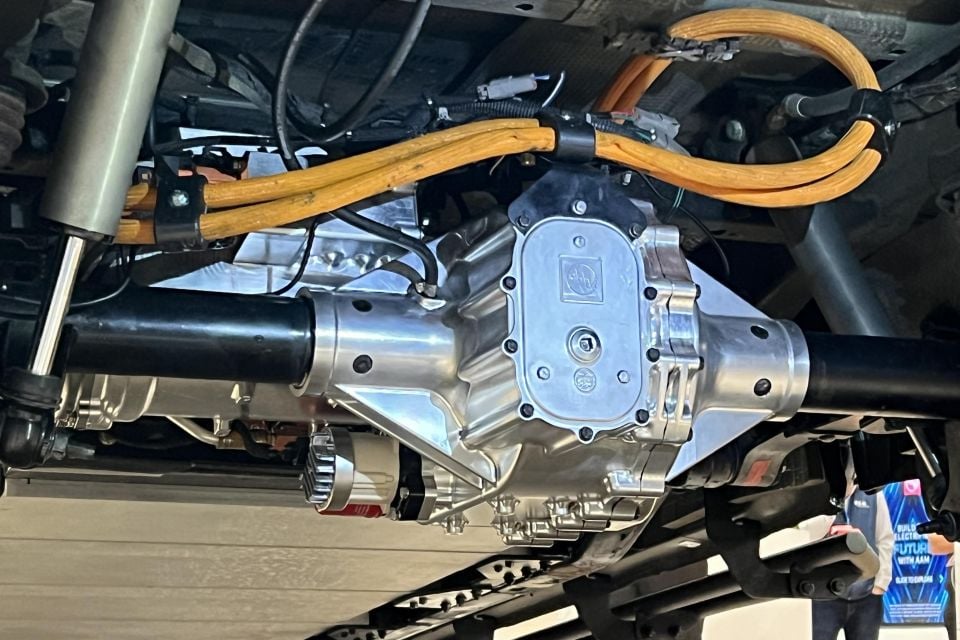

AAM has taken an American pickup truck and substituted the petrol drivetrain for its electric drive units and e-Beam technology.

Contributor

Contributor

As the industry embraces electrification, many companies are developing compact, multi-faceted technologies that can transform current and new vehicles from internal combustion to electric power.

While I may not be a big believer in electric vehicles (EVs) being the end-all solution for our community, industry and environment, there’s certainly some impressive technology being developed in an attempt to smooth out the transition from the much loved internal combustion engine (ICE) to the apparently clean, green and politically correct electric drive systems.

Of particular note at this year’s Consumer Electronics Show (CES) were the offerings from American Axle & Manufacturing (AAM), a Detroit-based company at the forefront of assisting some of the world’s biggest automakers in transitioning to electric drivetrains by creating new and innovative vehicle technologies for cars, utes and SUVs.

CES is a wonderland for geeks, tech-heads and anyone interested in, or fascinated by, technology, hardware and software advancements. It’s a global stage for innovation and is the most influential tech event in the world where breakthrough technologies and global innovators celebrate, launch and promote their latest developments.

AAM is an automotive and accessory manufacturer, and designs, develops and builds driveline and metal-forming technologies to support electric, hybrid and internal combustion-powered vehicles.

Past work by AAM includes the electric driveline technology found in the Mercedes-AMG GT 63 S E Performance.

At CES 2024, AAM showcased its award-winning, next-generation 3-in-1 electric drive units (eDUs), fully integrated e-Beam axles, and innovative component technologies.

“As the industry continues to transition to hybrid and electrified vehicles, we are proud of the products and technologies our engineers are developing,” said AAM chairman and CEO David C. Dauch.

“We are in a great position to provide OEMs with a full portfolio of products from EV components to fully electric drive systems.”

On show were some of AAM’s market-ready Electric Drive Technology systems along with a team of AAM experts primed and ready to answer any questions.

A standout feature though was their latest Battery Electric Truck.

AAM engineers have modified a production light-duty truck, a GMC Sierra 1500 powered by an internal combustion engine, and transformed it into a specially designed battery-electric truck featuring AAM’s 3-in-1 high-speed electric drive unit (eDU) and e-beam technologies.

The latter means a solid axle remanufactured to house an electric motor, gearbox and inverter.

This 1500 series truck features a single 150kW eDU driving the front wheels and a 430kW e-beam in the rear. The 3-in-1 design in both the front and rear integrates AAM’s proprietary motor, inverter and gearbox technologies into a single assembly for advantages in packaging, cost, performance and simplified integration into vehicle platforms.

Concerns regarding unsprung mass have been dealt with by utilising smart suspension tweaks and any weight gained by adding a larger battery, eDU and e-beam, are offset considerably by the removal of the ICE, gearbox and transfer case.

This in turn greatly eases the difficulties of converting current vehicles from combustion power to fully electric drivetrains, as there are no issues in adapting and aligning respective driveshafts and a transfer case.

Furthermore, the front and rear axle assemblies retain the same OEM suspension setups and the AAM systems are a direct retrofit.

The result is a carbon-friendly (let’s just leave it at that for now), clean energy, fully electric vehicle with an improved centre of gravity and a total of 580kW under foot! That is a quick truck in anyone’s language.

We are yet to see actual performance figures or any real-world tests for how these units handle towing, what the range is and how they cope with harsh off-road environments but for general street duties and typical truck work roles, we reckon those 580kW could certainly be put to good use!

So what do you think? Is this something you would drive? Do you think this is a positive step in the hunt for sustainable mobility and carbon net zero solutions? Let us know in the comments below!

James Wong

1 Hour Ago

CarExpert

3 Hours Ago

Derek Fung

5 Hours Ago

Matt Campbell

11 Hours Ago

Ben Zachariah

1 Day Ago

James Wong

1 Day Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.