William Stopford

Which new car should you buy for under $30,000?

10 Hours Ago

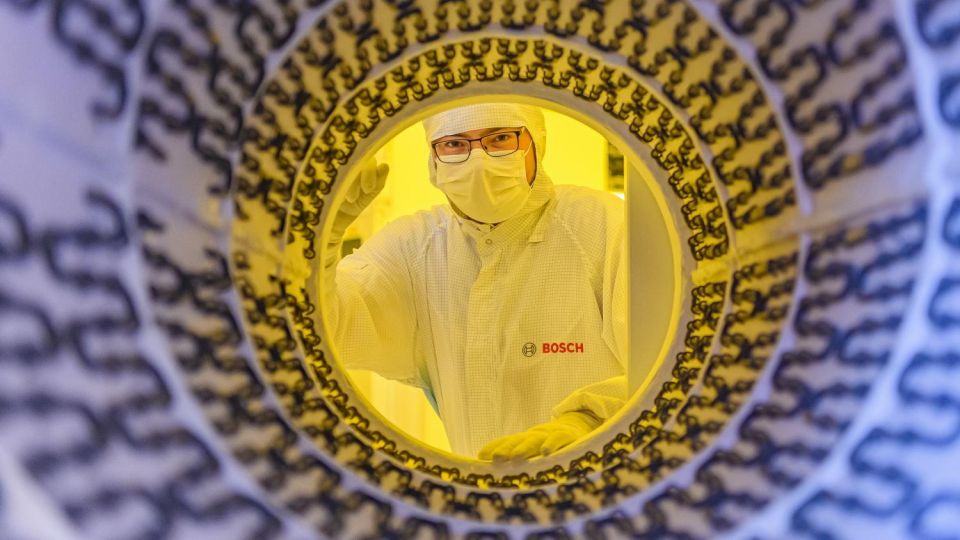

Bosch will put three billion euros in its semiconductor business by 2026, it claims, to make the supply chain more robust and future-ready.

Senior Contributor

Senior Contributor

Tier 1 auto supplier Bosch says it will pump three billion euros ($A4.46b) into its semiconductor chip division between now and 2026.

The lack of these chips in the broader supply chain has been one major factor crippling factory output in recent times – which in turn has driven record wait times for new cars and all-time high used-car prices.

This problem is amplified by the fact electric cars use more of them than combustion vehicles do, so it’s an impediment to lowering CO2 as well.

MORE: Staggering impact of semiconductor shortage on car industry revealed

While the funding out to 2026 won’t help alleviate today’s shortages, it should eventually make supply chains more capable of absorbing shocks. The wider strategic aim is to enhance Europe’s standing as a chip-maker – an area where it’s presently a minnow.

Under the umbrella of the ‘European Chips Act’, the European Union and federal government want to double Europe’s share of global semiconductor production from 10 to 20 per cent by 2030.

Bosch’s plans include €170 million for new development centres in Reutlingen and Dresden, Germany, and another €250 million to build a further 3000 square-metres of ‘clean room’ production space at its billion-euro Dresden plant.

The plan is to make an array of chips from 40 to 200 nanometres, suited to different industries not limited to cars.

Bosch claims the overall Dresden semiconductor plant that’s set for expansion and has been operational since June 2021 is the biggest single investment in its long history.

Since the end of 2021, Bosch says it has been mass-producing silicon carbide chips used in the power electronics of electric and hybrid cars, which it says can increase the range of EVs by up to six per cent. Order books, it says, are absolutely chockers and up 30 per cent this year.

Bosch says it’s now examining the development of gallium nitride chips “for electromobility” like those already used in laptop and smartphone chargers. For use in vehicles, these chips must be more robust and withstand significantly higher voltages than before, up to 1200V.

“Challenges like these are typical for Bosch engineers. Our advantage is that we have long been at home in microelectronics as well as in cars,” the company claims.

“Microelectronics is the future and a key success factor for all Bosch business areas. With it, we hold a central key for the mobility of tomorrow”, said Bosch chairman Dr Stephen Hartung.

“In the interest of our customers, we are preparing ourselves for an unabatedly growing demand for chips. For us, there is big business in the smallest components.”

Get a move on!

MORE: Bosch again increases chip output – but not until 2025 MORE: Bosch buying Melbourne motorsport tech company MoTeC

William Stopford

10 Hours Ago

Josh Nevett

10 Hours Ago

Max Davies

10 Hours Ago

Shane O'Donoghue

18 Hours Ago

Derek Fung

20 Hours Ago

James Wong

24 Hours Ago