Damion Smy

Ford posts its biggest loss since the Global Financial Crisis

8 Hours Ago

Contributor

Group B rallying. Mention this phrase to any motorsport enthusiast and they’ll immediately think of powerful vehicles tearing up dirt and gravel tracks, zooming past spectators often standing only a few metres away.

Group B was banned after a spate of fatal accidents in 1987, some involving spectators. In its rationale for prohibiting these vehicles, the governing body for motorsport at the time said drivers couldn’t control them on the tight, twisty, rough roads rally fans love.

Even for professional racing drivers, these cars were too fast.

Although it was short-lived, Group B and its relaxed regulations provided carmakers the opportunity to push the performance envelope to its technological and physical limits. The scope of innovation was increased, and the Audi Quattro was born.

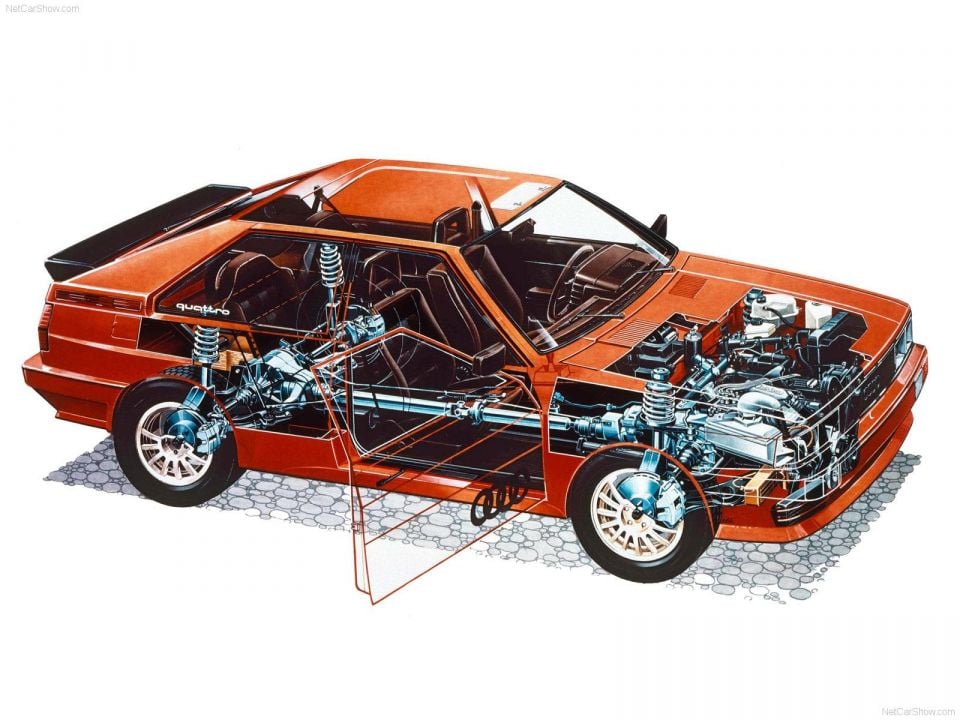

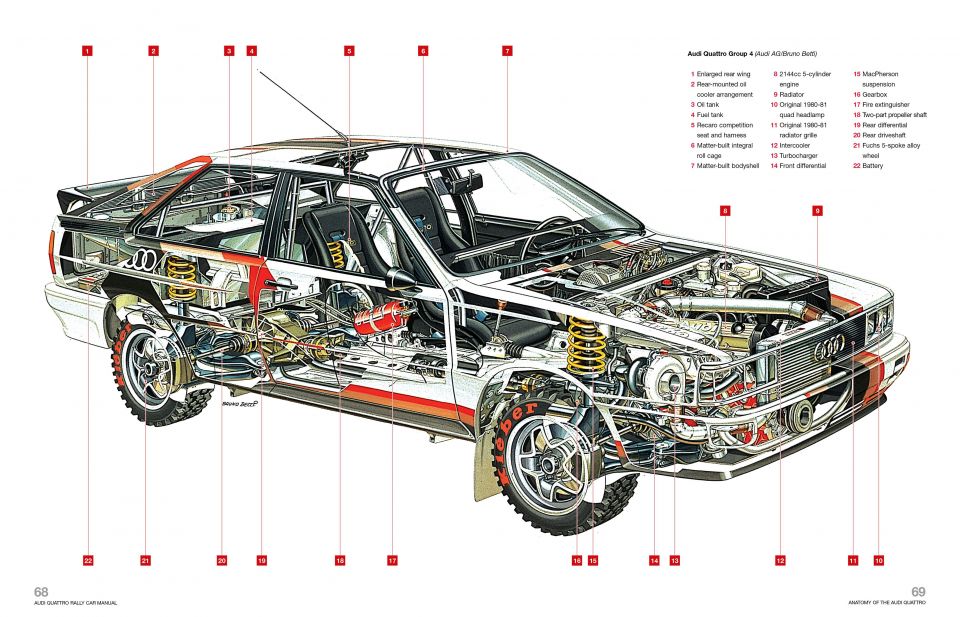

Audi wanted to gain a leg-up on its competitors through the use of an all-wheel drive (AWD) rally car, sending power to all four wheels rather than only the front or rear wheels.

Group B homologation rules meant that to compete, a run of at least 200 road-going versions of the car had to be produced – and both the road and rally versions of the car were known as the Audi Quattro.

From 1981-85 the rally car was hugely successful. It notched up 23 race wins in total, including winning the Portuguese rally three times consecutively from 1982-84. The road car had an 11-year production run from 1980-1991, with over 11,000 produced.

A word on nomenclature. Today, the uncapitalised word ‘quattro’ is used to describe the all-wheel drive system of any Audi, while the capitalised word ‘Quattro’ refers to the original 1980 car specifically.

‘Quattro’ is also interchangeable with ‘Ur-Quattro’ which is a German phrase referring to the ‘original Quattro.’

The fundamental principle behind all-wheel drive systems in performance cars is that driving all four wheels enables a vehicle to put its power down more effectively compared to a car that is only driving its front or rear wheels.

While four-wheel drive systems were common on commercial and off-road vehicles (such as Jeeps and Land Rovers) at the time, they had not been commonly applied in a performance context, especially for a vehicle designed to stay on the road.

In fact, Audi’s peers at the time doubted the need for an all-wheel drive system for a road-going car, believing it to add unnecessary weight and expense for insignificant benefit.

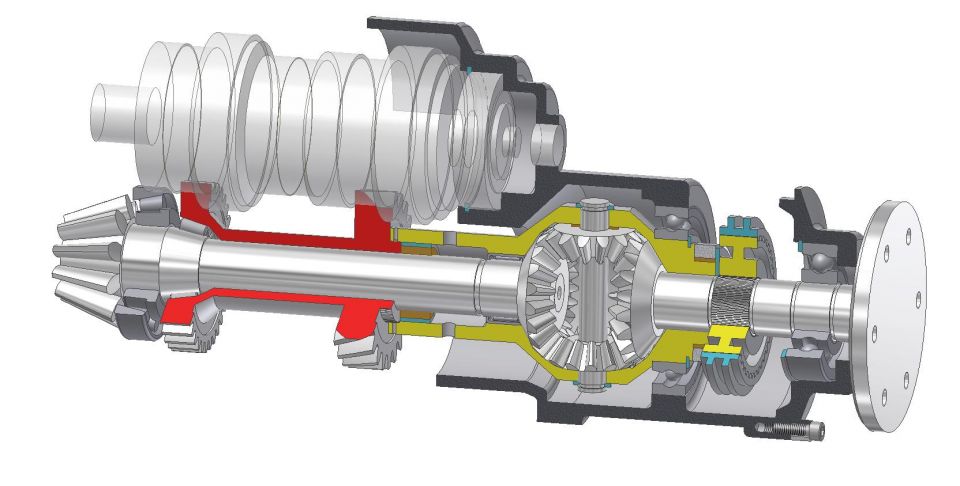

Compared to commercial and off-road applications, the primary innovation with Audi’s all-wheel drive system was the use of a 26.3cm-long hollow secondary shaft as part of the transmission. This was used to distribute power across all four wheels through an inter-axle differential.

Both the inter-axle and rear differentials were nominally open, but were manually lockable via switches on the centre console and coupled with an open front differential.

This was a much lighter alternative than the traditional use of a transfer case with multiple propeller shafts, a separate centre differential, and low-range gears to distribute power.

Audi’s system facilitated a 50:50 torque split across the front and rear axles without packaging constraints or requiring high ground clearance, making it better suited to road and track use.

The all-wheel drive system also helped compensate for other deficiencies in the Quattro. The engine was placed beyond the front axle which created a nose-heavy 60:40 weight distribution that, coupled with slow steering, would have compromised vehicle handling.

However, the added traction from the all-wheel system (combined with a driving style adjustment from Audi’s pilots, naturally) helped compensate for this.

The Quattro wasn’t the first turbocharged production car, with Porsche and Saab having pioneered the technology in the 1970s with models such as the 911 Turbo and 99 Turbo respectively.

However, the Quattro helped popularise the use of an intercooler to improve performance. Specific details of how turbocharging and an intercooler works can be found here. In short, an intercooler cools the air passing through it.

As the air cools, its density increases and a greater volume of air per unit of time can be transferred into the combustion chamber, increasing power.

The turbocharger and intercooler were necessary for the road-going Quattro and its low-displacement (2.1-litre) five-cylinder engine to lend credence to its sporting intentions.

The use of an intercooler and turbocharging system helped Audi extract a power output of 147kW with 285Nm of torque, propelling the car from 0-100km/h in 7.1 seconds. These figures remain competitive with warm hatches today.

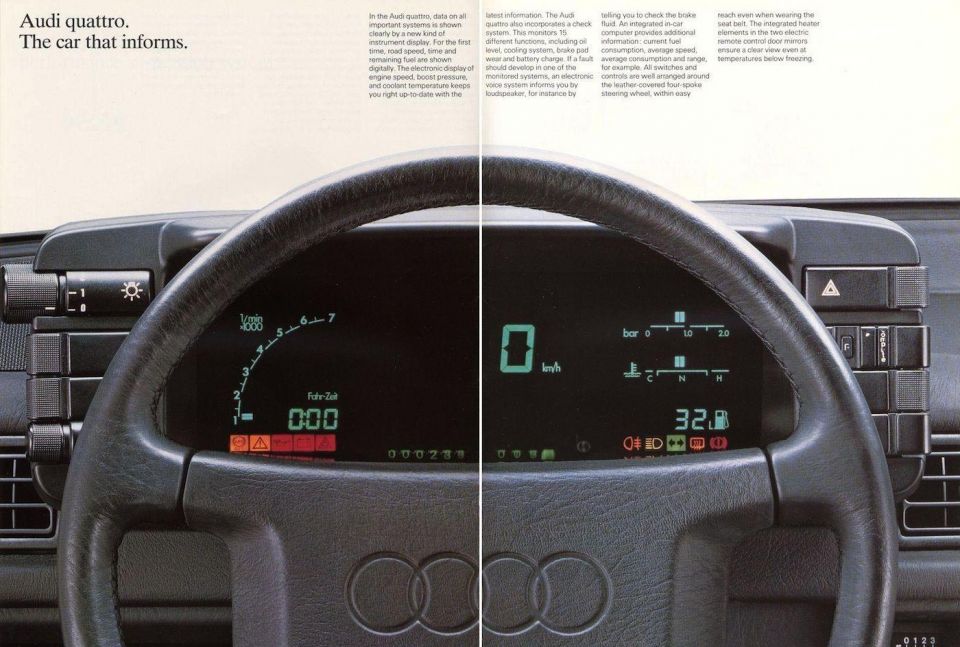

Audi and other marques from the wider Volkswagen Group are renowned for their industry-leading instrument clusters, featuring large, high-resolution LCD displays that can show everything from the speed to detailed satellite imagery through Google Earth.

Audi has a long history with advanced instrument clusters. In true 1980s sci-fi fashion, the Quattro was one of the first vehicles available to use an entirely digital instrument cluster from 1983 onwards.

High-resolution LCD displays had not been commercialised at the time, so the Quattro made use of green LEDs (similar to a typical bedside alarm clock) to show everything from the speed to the tachometer and the fuel gauge.

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

Damion Smy

8 Hours Ago

Damion Smy

8 Hours Ago

Ben Zachariah

10 Hours Ago

William Stopford

12 Hours Ago

Damion Smy

14 Hours Ago

William Stopford

14 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.