Derek Fung

BYD Atto 3: Much more powerful rear- and all-wheel drive models approved for sale

1 Hour Ago

eFuels are a new, potentially carbon neutral way to power our combustion-engined cars. How do they work, and what is Australia's role?

Contributor

Contributor

Demand for electric vehicles is obviously increasing at a huge clip, and they are widely expected to be the main type of vehicle in the decades to come.

However, they currently represent a minuscule share of the total new car market, with the vast majority of the world’s automotive fleet still using an internal-combustion engines – whether by itself or as part of a hybrid arrangement.

This raises the issue of whether there is anything that can be done to reduce the emissions and carbon footprint of vehicles already on the road today. eFuels are one potential answer to this problem.

They’re also potentially a way to keep thirsty, noisy, emotional internal-combustion engines alive in small quantities as the world goes electric.

The term ‘eFuel’ stands for ‘electrofuel’, with the electro component of this word denoting that electrolysis is an essential step in the production of eFuels. eFuels are also commonly known as synthetic fuels.

In short, eFuels have the potential to be produced in a sustainable way, that recaptures atmospheric carbon dioxide during the production process, helping to offset any carbon dioxide emissions released when an eFuel is burned by a vehicle, and allowing for close to net-zero emissions.

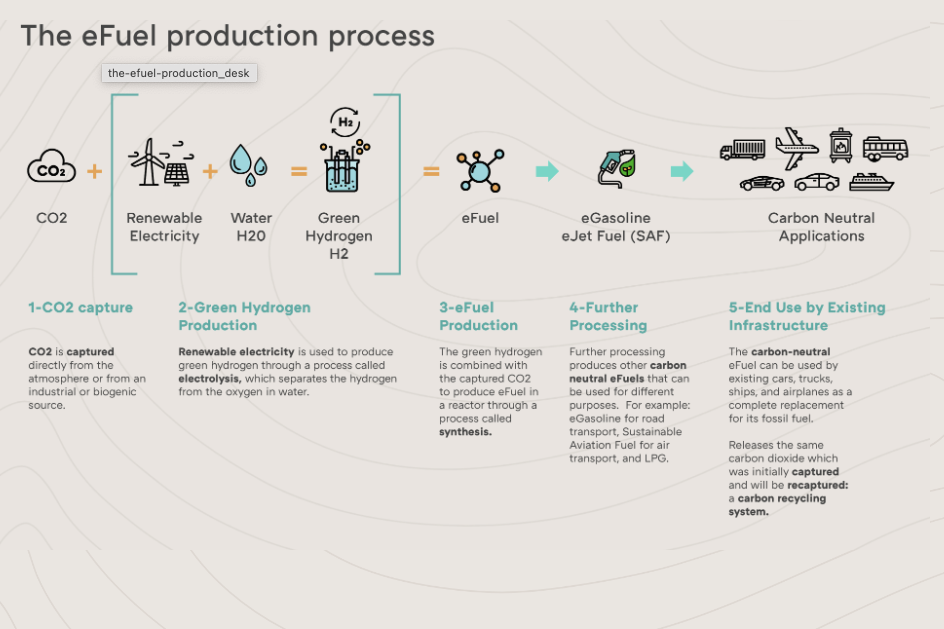

Recapturing this carbon dioxide acts as the first step of the eFuel production process, with the eFuel manufacturer using various techniques to capture CO2 directly from the air, or from other sources in the environment.

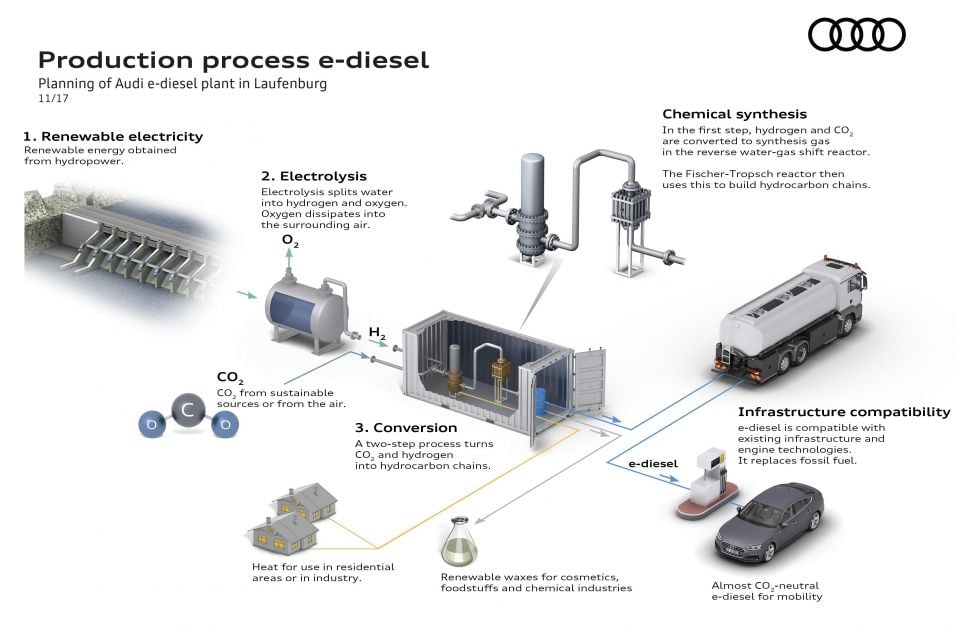

A separate renewable electricity source, such as hydroelectricity or solar power, is used to produce hydrogen in a sustainable manner by powering a technique known as electrolysis, whereby an electric current is applied to separate hydrogen atoms from oxygen in water.

Next, this sustainably-produced hydrogen is combined with the previously recaptured carbon dioxide in a plant, through a process known as synthesis, to produce eFuel, typically in the form of methanol.

Methanol in certain cases can be used directly to power vehicles, or refined/converted further, such as through the methanol-to-gasoline process invented by oil giant ExxonMobil, to be used as a substitute for naturally sourced fossil fuels such as petrol and diesel.

The primary benefit of eFuels is that they have a substantially lower overall carbon footprint compared to naturally-sourced fossil fuels, with car manufacturers such as Porsche claiming an 85 per cent reduction in total carbon dioxide emissions.

While burning eFuels will release CO2 in a similar fashion to fossil fuels, synthetic fuels burn cleaner. Compared to conventional fossil fuels, which have between 30 and 40 components, synthetic fuels have as few as eight.

Their production process also captures carbon dioxide initially from the environment, helping to offset any emissions. Total emissions are close to net-zero.

Moreover, synthetic fuel can theoretically be refined to have the same properties as diesel or petrol available today.

This means existing refuelling infrastructure such typical petrol stations and tankers could continue to be used, giving substantial cost savings.

Having the same properties as conventionally-sourced fossil fuel also means combustion-engined vehicles sold today should be able to eventually run on eFuel without modification, extending their lifespan.

This could be especially useful in developing markets that otherwise wouldn’t be able pay for an expensive EV charging network.

Currently, there also remain drawbacks with the eFuel production process. Whilst the basic scientific principles are well-understood, carbon capture and synthesis technologies are at a nascent stage of development, with comparatively large amounts of energy required to perform these processes.

Additionally, ensuring only renewable energy is used to power the electrolysis process remains a challenge, as this can often restrict the location or drive up the cost of the eFuel end product.

Porsche notes that once eFuel production has ramped up and economies of scale are achieved, it is targeting a wholesale price of $US2.00 per litre, equivalent to $2.88 a litre (AUD) based on current exchange rates.

This remains significantly more expensive than even 98 octane premium unleaded available today, being the price before taxes and other levies.

There is every chance that eFuel will be commercially available in various octane ratings much like standard and premium unleaded, and any high octane eFuel varieties would, of course, carry a greater cost.

Arguably the most high-profile car company that has made a significant commitment to eFuel is Porsche.

Recently the company announced it was making a $US75 million investment in HIF Global LLC, a holding company that develops, or invests in the development of, industrial eFuel production facilities, in return for 12.5 percent ownership of the company.

Porsche claims that this tranche of additional funding brings its total commitment to eFuels to more than $US100 million.

HIF Global LLC is, in turn, developing eFuel production facilities around the world, including in Punta Arenas, Chile, where wind power is expected to be a major source of energy for the electrolysis process.

MORE: Tasmania to produce eco-friendly eFuel for Porsche from 2026

More interestingly, however, is that HIF Global LLC has also committed to the development of an Australian eFuel production facility in Burnie, Tasmania.

With construction expected to begin in 2024, HIF expects the plant to begin eFuel production by mid-2026. Maximum expected production capacity is 190 tons of eFuel per day, or 100 million litres per year.

For this plant, HIF notes carbon dioxide will be sourced from biogenic (organic) sources, with electricity also being sourced from renewable sources.

Volkswagen Group stablemate Audi has also shown interest in eFuels, and in a 2018 press release claimed to be planning a pilot plant for the production of e-diesel, that would be able to produce 400,000 litres per year.

More recently, however, Audi has committed to phasing out combustion engines by 2026, and it is unclear to what extent the company will continue to invest in synthetic fuels.

With major efforts still being made to improve the efficiency of the eFuel production process, and production facilities still being rolled out, it is unlikely that eFuels will have widespread commercial availability until the late 2020s.

When eFuels do become commercially available, however, they are expected to be compatible with almost all existing petrol and diesel powered vehicles.

MORE: Which engine oil should you use? MORE: How to maximise electric vehicle battery longevity MORE: Filling it up, biodiesel and other biofuels MORE: Fuel ratings explained; 91, 95, 98 RON and E10

Derek Fung

1 Hour Ago

Ben Zachariah

8 Hours Ago

Ben Zachariah

8 Hours Ago

William Stopford

13 Hours Ago

William Stopford

15 Hours Ago

Damion Smy

17 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.