Derek Fung

Honda revises EV strategy after posting fourth straight quarterly loss

54 Minutes Ago

An Australian company will remanufacture EV batteries for a second life, or failing that turn them into stationary power storage.

Senior Contributor

Senior Contributor

A Melbourne-based startup called Infinitev has embarked on programs to refurbish end-of-life hybrid (HEV) and electric vehicle (EV) batteries for re-use in mobility or static storage.

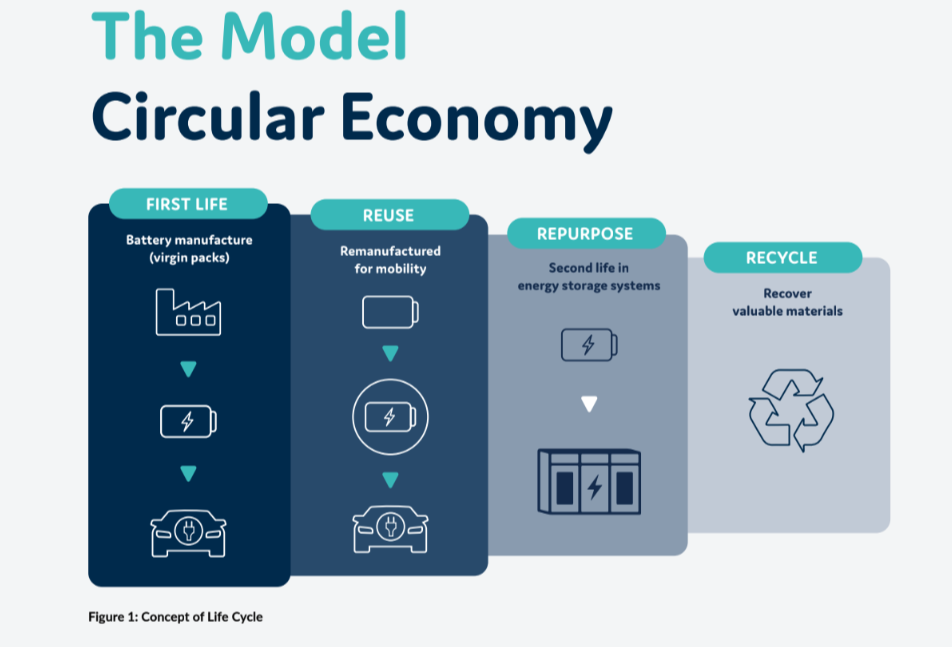

Rather than wasting a battery pack, often it’s possible to replace only the defective cells with an eye to the (slowly) burgeoning circular economy.

After all, batteries may be considered faulty with 70-80 per cent of their storage remaining under OEM warranty provisions, usually after six to eight years of service.

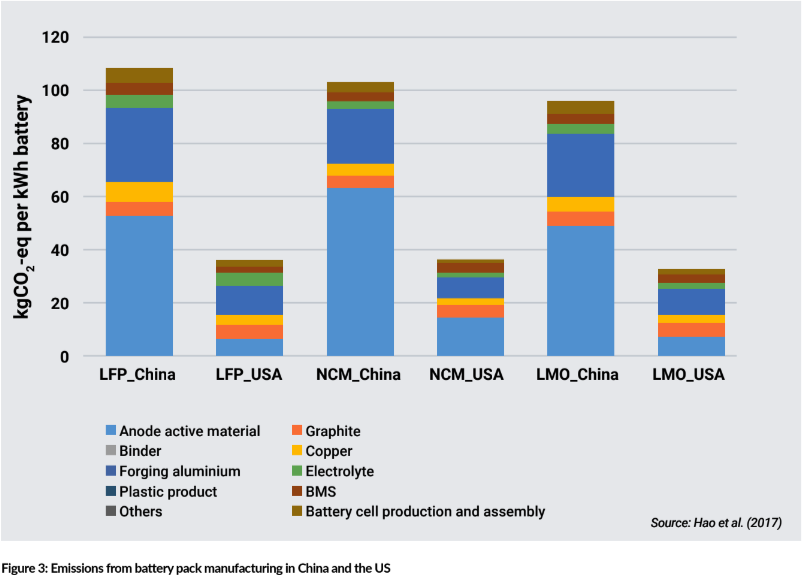

By reusing, repurposing, or at the least recycling HEV and EV batteries, the industry can make a serious impact on CO2 emissions and reduce the mining of raw materials.

Infinitev is part of the IM Group, a large Australasian mechatronics company. Sister brand Injectronics is a remanufacturer of engine control units, ABS braking systems, and body control modules

It intends to work with car companies, their franchise dealers, and aftermarket garages and wreckers to secure defective batteries, with various applications opening up from there. It calls this a way to erase current “pain points” around battery disposal and sourcing.

It’s also talking to peak industry bodies such as the FCAI (car brands) and AAAA (aftermarket), and has called for the creation of a singular national government framework legislating battery recycling and repurposing.

Reuse

Firstly there’s the scope for reuse, through a remanufacturing exchange project that right now is focused on hybrid vehicles – considering that market is far more mature, and many old HEVs need battery replacements already.

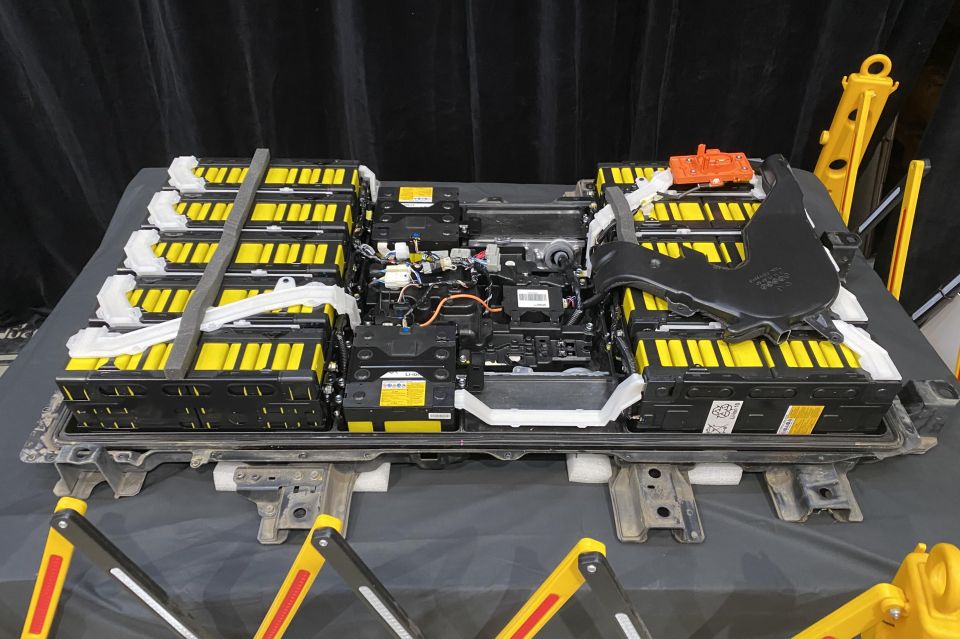

Infinitev will take away defective batteries, identify the problem, fix it with healthy modules, and on-sell it to customers or repairers. It’s currently running at 40-50 a month but says it will soon scale up, and move into a new facility.

It claims this second-life program could save customers $500 to $1000 over a new NiMH hybrid battery, with “exceptional performance” backed by a three-year warranty.

Infinitev says it plans to scale this service into full EVs, catering for various types of chemistries including lithium nickel manganese cobalt; lithium nickel cobalt aluminium oxide; and lithium iron phosphate.

These batteries are far larger and will naturally be more expensive, but the plan is to offer refurbished packs when there are lots of used EVs needing replacements later in the decade.

Repurpose

Another second (or third) life for EV batteries is to become stationary storage linked to rooftop solar or some other form of power generation, to either act as an industrial backup or even a principal source of off-grid power.

Developed in partnership with Sustainability Victoria, Infinitev’s Battery Energy Storage System (BESS) uses EV batteries no longer suited to vehicle applications.

The pilot BESS uses old Nissan Leaf batteries and stores 120kWh, and serves as a power source for Infinitev’s warehouse. Its target for commercial sales is March 2024.

Infinitev says its best bet is to focus on BESS units suited to small-to-medium size warehouses – rather than home batteries or gigawatt-scale storage linked to solar and wind farms. This it sees as a sweet spot.

For another example of this technology, some of you may recall a September announcement that Nissan Australia plans to use repurposed Leaf batteries to partially power the production of EV components at the Nissan Casting Australia Plant (NCAP) in Dandenong, Victoria.

Recycling

The automotive industry traditionally gets materials from the earth to manufacture batteries, and dumps the faulty product as waste.

But when batteries reach their end of life, and can’t be reused or repurposed, Infinitev says it will work with industry recycling programs to recover materials used to make new batteries.

It’s a member of the Australian Battery Recycling Initiative and Battery Stewardship Council.

One cited study found by 2030, at current rates, 200 gigawatt hours of EV battery storage will be wasted each year when defective packs are thrown out.

“Infinitev is unique in what it offers the automotive industry in the recovery and repair of faulty or end-of-life hybrid and electric batteries,” Infinitev General Manager Dickson Leow said.

“Infinitev is the only service provider in the industry that offers a three-pronged program that considers battery reuse, repurpose and recycling opportunities, and the circular economy advantages.

“Infinitev can enhance an organisation’s environmental and sustainability (green) credentials and eliminate waste.”

MORE: Meet Australia’s cheaper, cleaner hybrid battery replacements

Derek Fung

54 Minutes Ago

Ben Zachariah

7 Hours Ago

James Wong

7 Hours Ago

James Wong

7 Hours Ago

James Wong

7 Hours Ago

Damion Smy

14 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.