Ben Zachariah

2026 KGM Musso EV review

6 Hours Ago

The ballistic Mercedes-AMG One hypercar is billed as the most ambitious project the company has ever undertaken.

Contributor

Contributor

Mercedes-AMG has started building its first customer-bound One at a specialised production facility in the UK ahead of delivery in the second half of 2022.

Pitched as a Formula 1 car for the road, the Mercedes-AMG One has been in the works for a very, very long time.

Initially meant to launch in 2019, the One had been held back by the challenge of making a powertrain derived from F1 work on the road, and meet ever-tightening emissions standards.

Only 275 examples of the Mercedes-AMG One are going to be built and every single one is going to be hand-made in partnership with Canadian engineering and manufacturing firm Multimatic.

There are 16 different assembly and testing stations in the production of a Mercedes-AMG One, which the German high-performance automaker likens to “production of high-quality luxury watches”.

Mercedes-AMG says a number of the One’s “sub-systems” are first pre-assembled and then tested to make sure they work, to then be disassembled again and finally installed to the vehicle.

As an example, this applies to the carbon-fibre monocoque chassis with its bonded-in roof and detachable body panels.

Each exterior body panel is fitted to the chassis to ensure that everything fits properly and can be adjusted if necessary.

Once everything is “perfect”, the body panels are dismantled and then hand-painted as a car set to ensure “perfect colour match of the entire vehicle”.

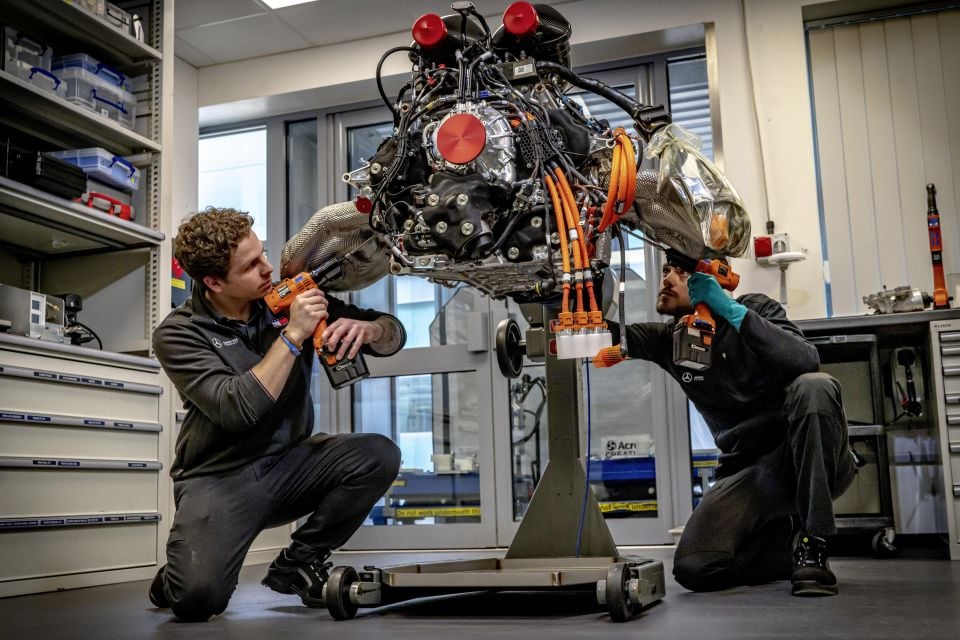

The next major production stage includes assembling the F1-derived hybrid powertrain and the body-in-white, which refers to when the car’s chassis has been joined together.

Mercedes-AMG High Performance Powertrains (HPP) is the company that builds Formula 1 engines for the German automaker’s F1 cars, and also builds the engine components for the One.

Mercedes-AMG says that 75 per cent of the parts for the One are already assembled before the high-voltage components are installed.

The final stage of production is “final acceptance testing” at a nearby proving ground where it’s tested by a factory test driver.

Once the One has been given the tick of approval, the vehicle is given “appropriate transport protection” and transported in a closed truck to Mercedes-AMG’s headquarters in Affalterbach, Germany for the handover.

In total, there are over 50 “specialists” who work on each Mercedes-AMG One.

“The Mercedes‑AMG ONE is the most ambitious project we have ever undertaken – from development to production,” said Mercedes-AMG chairman of the board of management Philipp Schiemer.

“This world first is now becoming a reality thanks to the great teamwork between Mercedes‑AMG in Affalterbach, the Formula 1 experts at Mercedes‑AMG High Performance Powertrains in Brixworth and our production partner Multimatic.”

The Mercedes-AMG One is powered by a 1.6-litre turbocharged hybrid V6 engine that produces 422kW of power and four electric motors that produce 450kW. It also has a 8.4kWh battery pack.

One of these electric motors is an F1-style MGU-K mounted to the crankshaft, two more are mounted to the front axle, and the last is mounted to turbocharger to slash lag.

Total system output is 782kW of power and the top speed is electronically limited to 352km/h.

With a claimed kerb weight of 1695kg, the 100km/h sprint takes a claimed 2.9 seconds, the 200km/h sprint takes 7.0 seconds, and the 300km/h sprint flies by in 15.6 seconds.

Go deeper on the cars in our Showroom, compare your options, or see what a great deal looks like with help from our New Car Specialists.

Jack Quick is an automotive journalist based in Melbourne. Jack studied journalism and photography at Deakin University in Burwood, and previously represented the university in dance nationally. In his spare time, he loves to pump Charli XCX and play a bit of Grand Theft Auto. He’s also the proud owner of a blue, manual 2020 Suzuki Jimny.

Ben Zachariah

6 Hours Ago

James Wong

6 Hours Ago

James Wong

6 Hours Ago

James Wong

6 Hours Ago

Damion Smy

13 Hours Ago

William Stopford

14 Hours Ago

Add CarExpert as a Preferred Source on Google so your search results prioritise writing by actual experts, not AI.